Water Vapor Transmission Rate Tester

Introduction of Water Vapor Transmission Rate Tester

This product is based on the infrared moisture analysis sensor testing principle, offering a wide range and high-efficiency water vapor transmission rate detection experience for medium and high water vapor barrier materials. It is suitable for testing the water vapor transmission properties of plastic films, composite films, high-barrier materials, backboards, sheets, paper, metal foils, packaging materials, and related materials in fields such as food, pharmaceuticals, medical devices, daily chemicals, photovoltaic electronics, etc. It can also be extended to test the water vapor transmission properties of containers such as bottles, bags, and tubes.

Detail Features About Gas Permeability Tester

- Laser Pulse-Modulated Infrared Sensor: Equipped with a laser pulse-modulated infrared sensor for long light path absorption, achieving higher measurement accuracy.

- Independent Multi-Chamber Design: Three fully independent test chambers allow simultaneous testing of three identical or different samples (extendable to container testing).

- Comprehensive Automated Control System: One-touch operation with a fully intelligent computer-controlled system, automating the entire testing process.

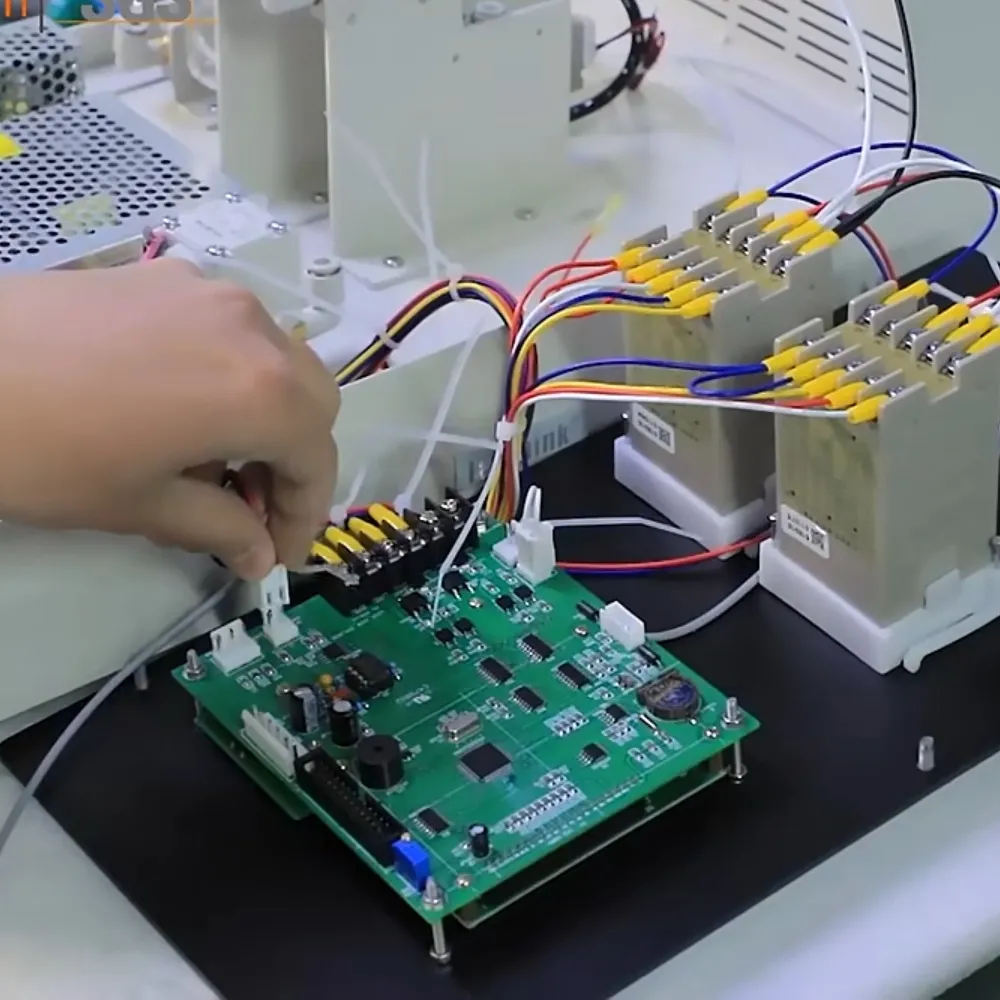

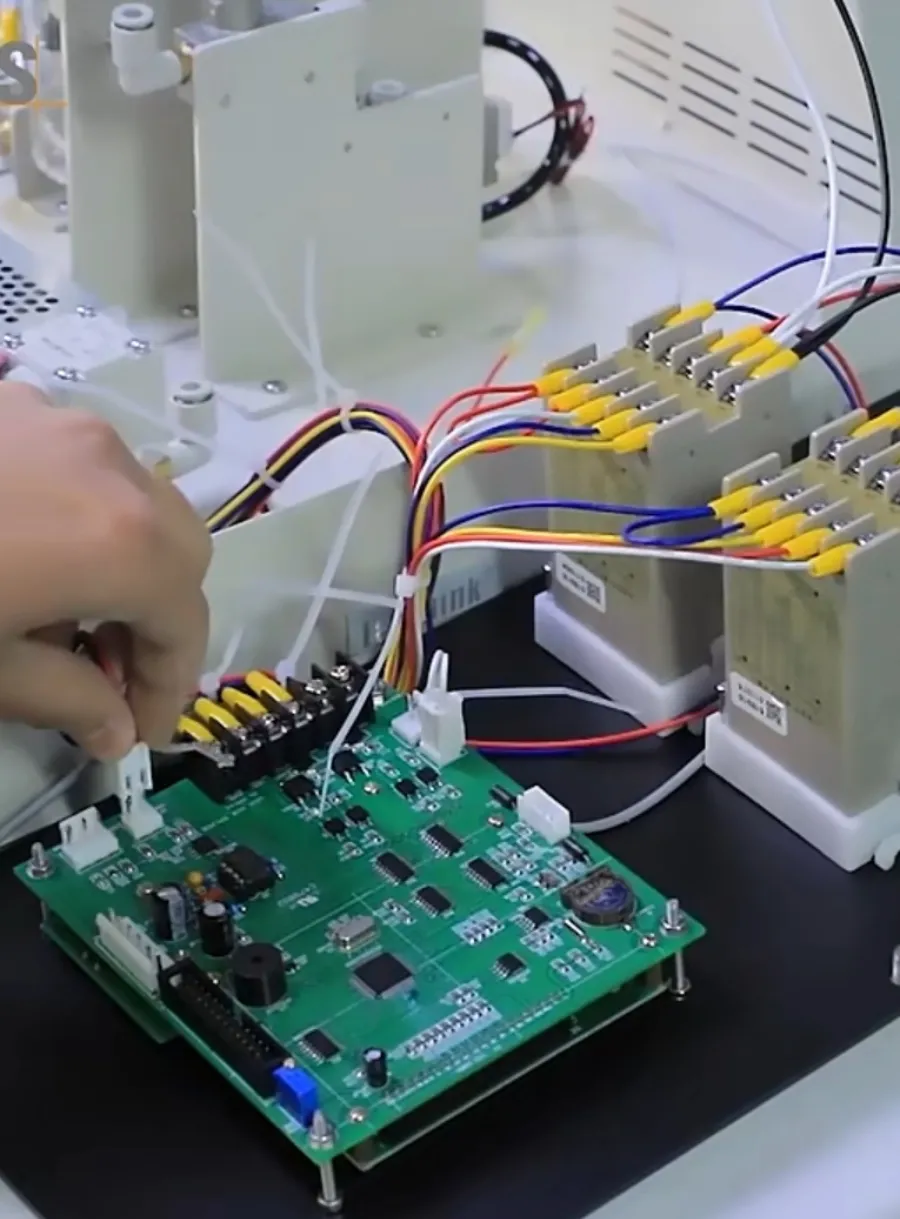

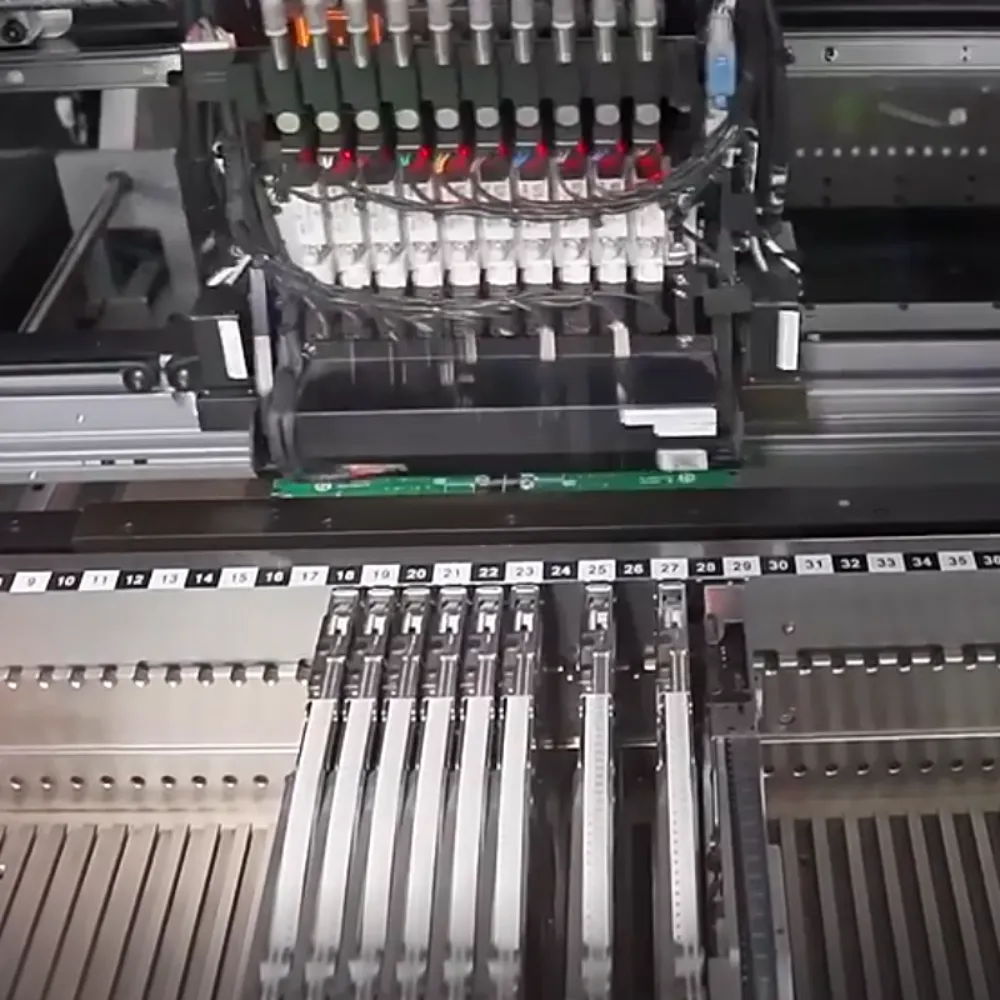

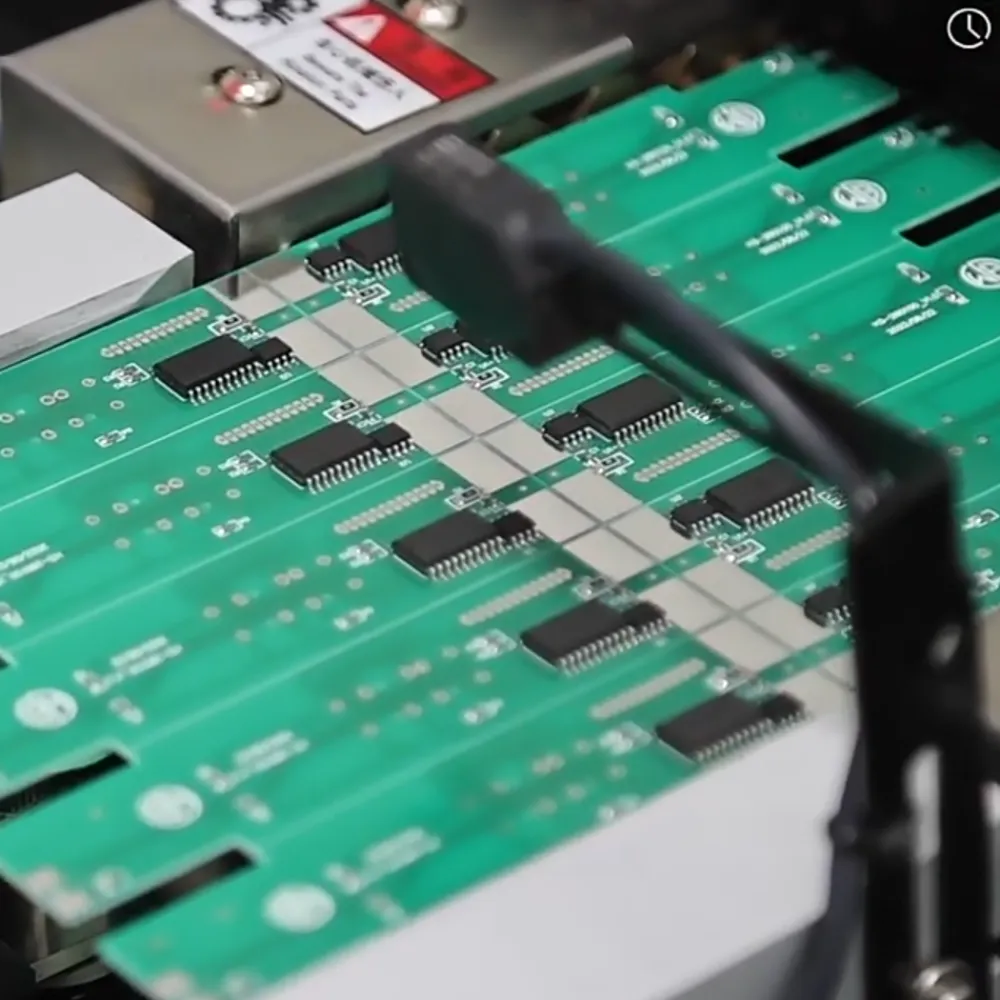

- High-Quality Components: Utilizes high-quality components to ensure the instrument’s stability and reliability.

- Automatic Testing: Set test parameters and start testing; the system automatically conducts the test, determines when it is completed, and saves the test results.

- Intelligent Software Monitoring: Standard intelligent software provides real-time monitoring of test status and preserves test data throughout, facilitating post-evaluation of the testing process.

- Self-Diagnostic and Data Protection: The system has self-diagnostic capabilities and data-saving functions during power outages to protect data integrity in case of faults or sudden power loss.

- Advanced Temperature and Humidity Control: Wide range, high-precision, fully automated temperature and humidity control automatically meets various testing conditions based on parameter settings.

- Multiple Testing Modes: Provides multiple test process judgment modes, including manual, proportional, and cycle, to accommodate various testing requirements.

- Expandable Test Range: Test range can be expanded as needed to meet high-permeability testing requirements.

- Quick Calibration with Standard Membranes: Provides standard membranes for quick calibration, ensuring the accuracy and universality of detection data.

- Automated Water Bath Temperature Control: Utilizes fully automated water bath hot and cold cycle temperature control technology, offering a wider temperature control range, unaffected by external environmental interference, and low requirements for the laboratory testing environment.

- Pneumatic Automatic Clamping: Test chambers are equipped with pneumatic automatic clamping devices, allowing one-touch automatic clamping of samples, facilitating easy and quick operation, and ensuring more reliable sealing.

- Precision Baseline Technology: Utilizes extreme zero-point and sealed pipeline systems with baseline technology to eliminate system errors, resulting in more precise test results.

- High-Precision Mass Flow Meters: Features high-precision mass flow meters with automatic flow control without manual intervention, ensuring data stability during the testing process.

- Professional Pipeline Flushing: Professional test pipeline flushing technology accelerates test speed and increases testing efficiency.

Built-in cooling fans on both sides: better heat dissipation, improved machine performance and extended machine life

- Clean Carrier Gas System: Professional test pipeline sealing system ensures the cleanliness of the carrier gas.

- Gas Flow Monitoring: Equipped with gas flow monitoring functions, automatically alarms when gas is low or absent.

- Encrypted Database System: Main unit software features an encrypted database system, allowing storage, querying, printing, exporting, and other functions for test data.

- Universal Data Interfaces: Equipped with universal data interfaces such as RS232 and USB for easy data transmission.

- Customization Services: Offers professional software, hardware, and special function customization services to meet users’ personalized needs for fixtures, software operations, and more.

- GMP-Compliant Software (Optional): Optional software compatible with China’s GMP data traceability requirements, offering multi-level access management, audit tracking, electronic signatures, etc., fully meeting the needs of the pharmaceutical industry.

Testing Principle of Gas Permeability Tester

Based on the infrared sensor method principle, moisturized nitrogen gas with a certain humidity flows on one side of the material, while dry nitrogen gas flows on the other side. Due to the humidity gradient, water vapor molecules diffuse through the film material from the high-humidity side to the low-humidity side. On the low-humidity side, the permeated water vapor molecules are carried by the flowing dry nitrogen gas (carrier gas) to the infrared sensor. The sensor generates corresponding electrical signals based on the concentration of water vapor carried by the carrier gas. By accurately measuring the sensor’s electrical signals, the water vapor transmission rate and other parameters of the sample can be calculated.

If the test object is a packaging item (such as bottles, boxes, etc.), the dry nitrogen gas flows inside the packaging item, while the nitrogen gas with certain humidity surrounds the outside of the packaging item.

Reference Standards:

GBT 26253, ISO 15106-2, ASTM F1249, TAPPI T557, JIS K7129, ISO 15106-3, DIN 53122-2, YBB 00092003

Testing Applications of Gas Permeability Tester

Basic Applications

- Films: Water vapor transmission rate testing of various plastic films, plastic composite films, paper-plastic composite films, coextrusion films, aluminized films, aluminum composite films, glass fiber aluminum foil paper composite films, and other film materials.

- Sheets: Water vapor transmission rate testing of PP sheets, PVC sheets, PVDC sheets, metal foil sheets, rubber sheets, silicone sheets, and other sheet materials.

- Paper, Cardboard, and their Composite Materials: Water vapor transmission rate testing of cigarette pack aluminum paper, paper-aluminum-plastic composite sheets, and other paper and cardboard materials.

Extended Applications

- Packaging Items: Water vapor transmission rate testing of plastic, rubber, paper, paper-plastic composite, glass, and metal materials such as wine bottles, cola bottles, peanut oil barrels, Tetra Pak packaging, vacuum bags, triple-layer cans, cosmetic packaging, toothpaste tubes, jelly cups, yogurt cups, etc.

- Packaging Item Lids: Water vapor transmission performance testing of various packaging item lids.

- LCD Displays: Water vapor transmission performance testing of LCD displays and related film materials.

- Solar Backboards: Water vapor transmission performance testing of solar backboards and related materials.

- Pipes: Water vapor transmission performance testing of PPR pipes and other material pipes.

- Pharmaceutical Blister Packs: Comprehensive water vapor transmission performance testing of pharmaceutical blister packs.

- Sterile Protective Films, Medical Ointment Patches: Water vapor transmission performance testing of sterile protective films and medical ointment patches.

- Battery Casings: Water vapor transmission performance testing of battery casings.

Technical Dates of Customized Gas Permeability Tester

Specification |

Parameter |

|---|---|

|

Measurement Range (Film) |

0.01~40 g/(m²·day) (standard) |

|

|

0.1~1000 g/(m²·day) (optional) |

|

Resolution |

0.001 g/(m²·day) |

|

Sample Quantity |

1~3 pieces |

|

Sample Size |

φ110 mm |

|

Transmission Area |

50 cm² (customizable) |

|

Sample Thickness |

<3 mm (customizable) |

|

Sample Clamping Method |

Pneumatic clamping |

|

Temperature Control Range |

5°C~65°C (constant temperature water bath control) |

|

Temperature Control Accuracy |

±0.1°C |

Specification |

Parameter |

|---|---|

|

Humidity Control Range |

0% RH, 5%~90% RH, 100% RH (fully automated control) |

|

Humidity Control Accuracy |

±1% RH |

|

Calibration Method |

Standard membrane calibration |

|

Carrier Gas |

99.999% high-purity nitrogen (carrier gas provided by user) |

|

Carrier Gas Flow Rate |

0~100 mL/min |

|

Gas Source Pressure |

≥0.2 MPa |

|

Interface Size |

1/8 inch metal pipe |

|

Dimensions |

1000 mm (L) × 580 mm (W) × 570 mm (H) |

|

Power Supply |

AC 220V 50Hz |

|

Net Weight |

60 kg |

Product Configuration of Gas Permeability Tester

- Standard Configuration: Main unit, computer, professional software, constant temperature control device, special sampler, vacuum grease, precision pressure reducer

- Optional Accessories: Container testing accessories, container temperature control device, sampling blades, vacuum grease

- Remarks: The gas inlet of the main unit uses a Ф6 mm polyurethane tube; gas source and distilled water are provided by the user.

Invest in High Tech Lab Equipment

Enhance your business profitability with this advanced device

Frequently Asked Question

The WTC-403H operates on the infrared sensor method. Humidified nitrogen gas flows on one side of the test material, while dry nitrogen flows on the opposite side. Due to the humidity gradient, water vapor molecules diffuse from the high-humidity side through the material to the low-humidity side. The dry nitrogen (carrier gas) then transports these water vapor molecules to the infrared sensor, which detects the moisture concentration. This signal enables precise calculation of the material’s water vapor transmission rate.

Yes, the WTC-403H is versatile and can measure the water vapor transmission rate for a wide range of materials, including plastic films, composite films, high-barrier materials, metal foils, and more. It can also test various packaging forms, such as bottles, bags, and tubes, with optional accessories, expanding its application across industries like food, pharmaceuticals, and electronics.

The WTC-403H uses advanced laser-modulated infrared sensors with high precision and long optical path absorption. Additionally, the system provides stable temperature and humidity control, accurate pneumatic clamping for samples, and comprehensive software for real-time data monitoring and automatic error checking. Calibration with standard films further ensures data accuracy and reliability.

Yes, the WTC-403H offers both automatic and manual modes for different testing needs. In automatic mode, users set the parameters, and the test is fully automated from start to finish. The system also includes multiple judgment modes, such as manual, proportional, and cyclic, allowing tailored testing workflows for diverse applications.

Advanced Differential Pressure Technology

Built on a highly accurate differential pressure testing principle, this gas permeability tester ensures reliable and precise measurements of gas transmission rates.

It is specifically engineered for a wide range of materials, making it versatile across industries for oxygen, carbon dioxide, nitrogen, and air permeability testing.

Independent Multi-Chamber Design

Equipped with three fully independent test chambers, this instrument allows simultaneous testing of up to three samples, which can be identical or different. This setup improves testing efficiency and flexibility, enabling labs to manage diverse testing needs with a single device.

Comprehensive Automated Control System

Featuring an intelligent one-touch operation system, this tester automates the entire process, from pressure control to test completion. Integrated software with data encryption ensures secure data handling, storage, and export, facilitating seamless data management and historical trend analysis.

Enhanced Customization and Safety Features

The tester is highly customizable, supporting specialized attachments for testing flammable, explosive, or toxic gases, along with GMP-compatible software options for industries with strict regulatory requirements. The system also offers robust self-diagnostic and data recovery functions to ensure continuous operation even under unexpected power outages.

Send us mail

Thanks for your inquiry, we will reply you within 12 Hours. Also you can add our WhatsApp for the quick reply.