Medical Packaging Material Mechanical Performance Tester

Introduction of Medical Packaging Material Mechanical Performance Tester

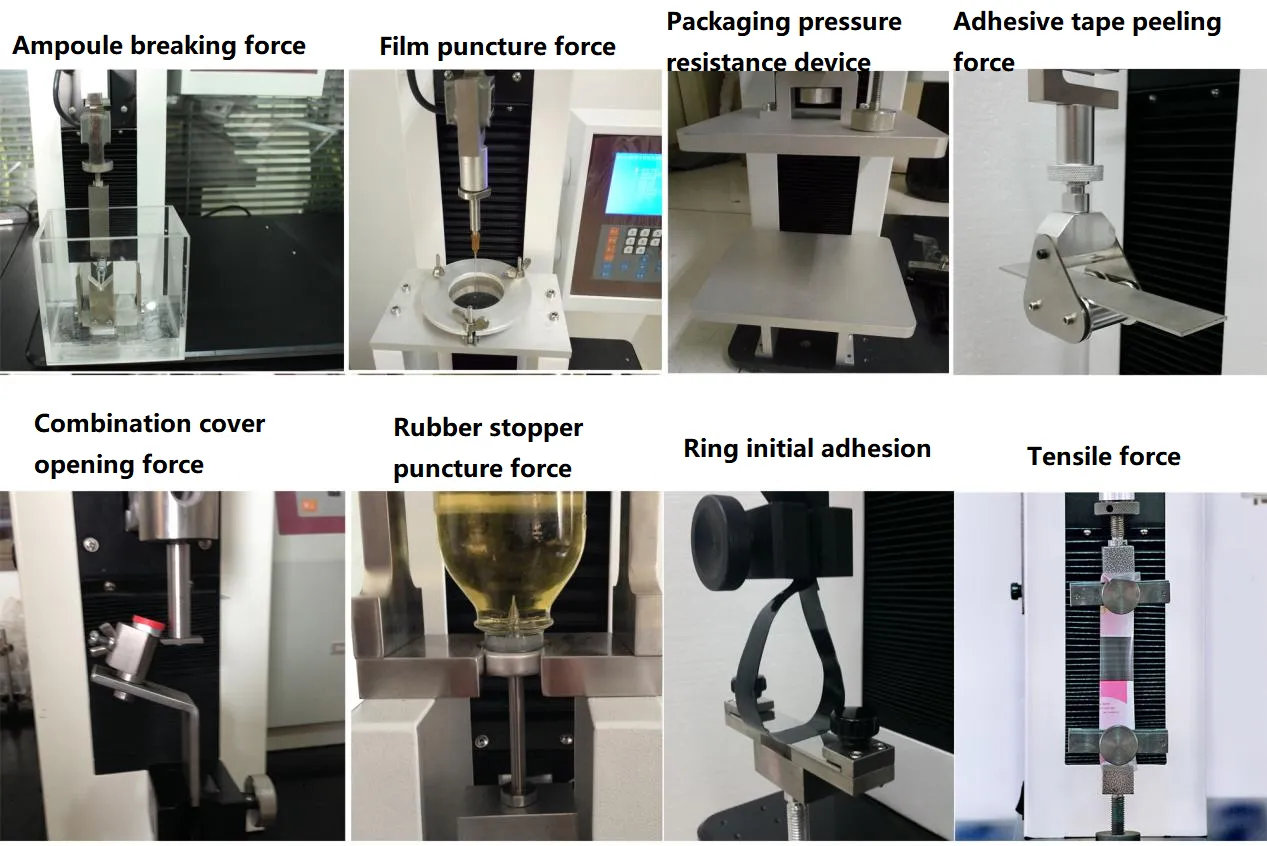

The Medical Packaging Material Mechanical Performance Tester, also known as the Tearing Force Tester, is designed according to the latest pharmaceutical packaging standards. It is primarily used for testing the heat-sealing strength, tensile strength, peel strength, elongation at break, and other properties of medical packaging materials, such as aluminum foil, PVC hard sheets, composite films, syringes, and cartridge bottles. It also performs tests on ampoule breaking force, opening and puncture forces for aluminum-plastic combination caps, aluminum foil tearing force, as well as syringe sealing, sliding performance, and needle-to-hub connection strength. This instrument is a multifunctional tester capable of various tests with different fixtures.

Detail Features About Medical Packaging Material Mechanical Performance Tester

Application Scope

- Pharmaceutical Rubber Stoppers

- Ampoules

- Aluminum-Plastic Combination Caps

- Composite Film Bags

- PVC Hard Sheets

- Pharmaceutical Aluminum Foil

- Syringes

- Menu-driven interface: Convenient and user-friendly; easy to learn, understand, and operate.

- Supports multiple test methods: including tensile, peel, opening force, puncture force, breaking force, piston mobility, and others.

- Large LCD screen: Full graphical display of real-time measurement data, variation curves, and test results.

- Independent test execution: Built-in micro printer for immediate printing of each test result.

- USB Interface: Equipped with professional control software for executing tests via software.

- Professional software: Displays real-time test data and variation curves, with data-saving and comparison features.

- Multifunctional operations: Allows setting parameters, printing, viewing, clearing, calibration, etc., for different test items.

- Protection features: Overload, limit, travel protection, and automatic reset after test completion.

Usage of Medical Packaging Material Mechanical Performance Tester

Technical Dates of Medical Packaging Material Mechanical Performance Tester

Parameter |

Specifications |

|---|---|

|

Measurement Range |

100, 200, 300, 500, 1000N (selectable) |

|

Measurement Accuracy |

0.5 grade |

|

Test Speed |

1–500 mm/min (adjustable speed) |

|

Measurement Stroke |

300 mm (excluding fixtures) |

|

Dimensions |

450 mm (L) × 450 mm (B) × 900 mm (H) |

|

Power Supply |

AC 220V 50Hz |

|

Weight |

50 kg |

Testing Principle of Medical Packaging Material Mechanical Performance Tester

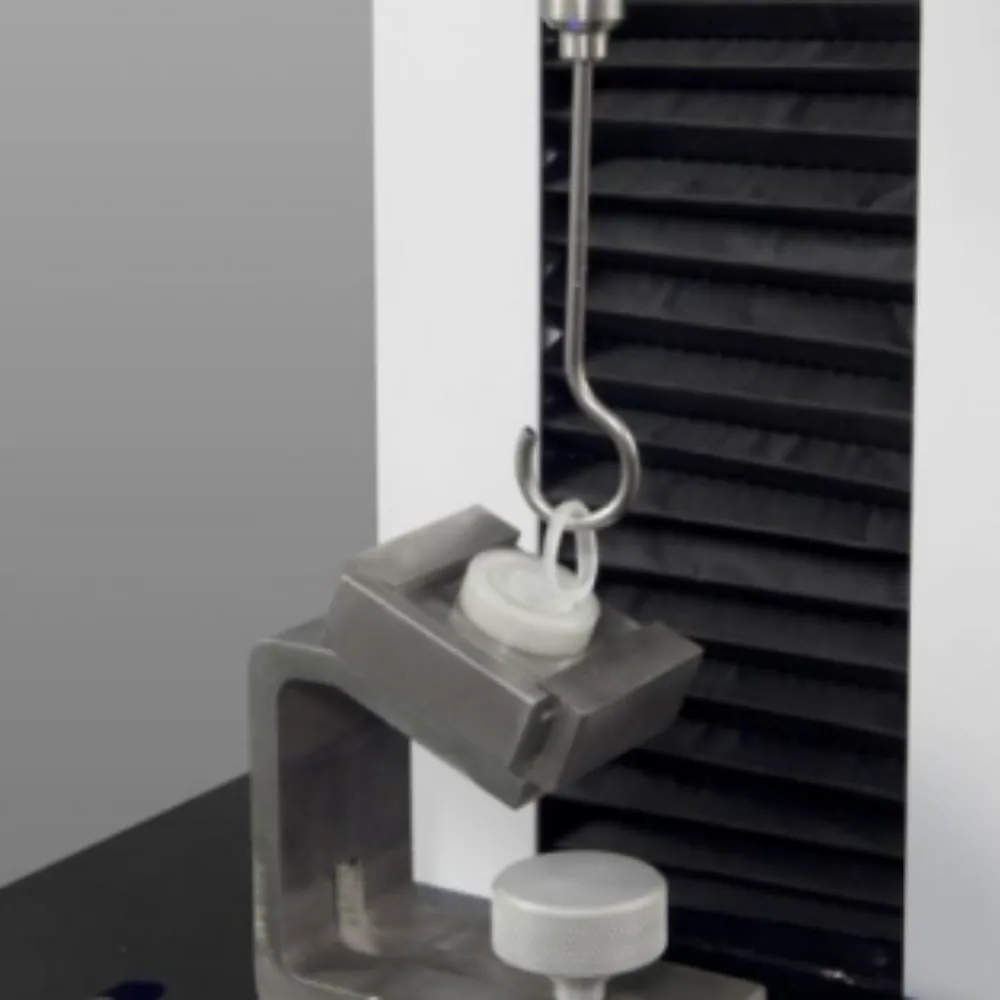

The sample is clamped between two clamps, which move relative to each other. With specialized clamps, puncture or opening force tests are conducted. The force value and displacement changes during this process are precisely measured by the instrument’s force measurement system, yielding the corresponding force data.

Standards

YBB00152002-2015, YBB00212005-2015, YBB00232005-2015, YBB00222005-2015, YBB00182004-2015, YBB00202005-2015, YBB00242002-2015, YBB00212004-2015, YBB00132005-2015, YBB00142005-2015, YBB00152005-2015, YBB00092005-2015

Configuration

- Standard Configuration: Main unit, universal tensile fixture, communication cable, power cable, technical documents

- Optional Additional Configuration: Breaking force fixture, rubber stopper puncture force fixture, pull ring opening force fixture, combination cap opening force fixture, cartridge bottle piston sliding performance fixture, syringe sealing test device, needle-hub connection strength test device, needle tube patency test device

Invest in High Tech Lab Equipment

Enhance your business profitability with this advanced device

Frequently Asked Question

The Medical Packaging Material Mechanical Performance Tester can conduct various tests, including tensile strength, peel strength, heat-sealing strength, puncture force, opening force, ampoule breaking force, syringe sealing, sliding performance, and needle-to-hub connection strength. It is versatile and supports multiple fixtures for different testing requirements.

Yes, the machine features a menu-driven interface that is user-friendly and easy to learn. It comes with a large LCD screen that displays real-time data, variation curves, and test results, making it simple for operators to use and understand.

The tester can perform tests independently without needing a computer. However, it also comes with USB connectivity and professional control software that allows the operator to control tests through a computer for enhanced functionality, including data saving and real-time monitoring.

The machine operates on AC 220V 50Hz and has compact dimensions (450 mm × 450 mm × 900 mm), making it easy to fit into most laboratory or testing environments. It weighs approximately 50 kg, so a stable setup area is recommended.

Advanced Differential Pressure Technology

Built on a highly accurate differential pressure testing principle, this gas permeability tester ensures reliable and precise measurements of gas transmission rates.

It is specifically engineered for a wide range of materials, making it versatile across industries for oxygen, carbon dioxide, nitrogen, and air permeability testing.

Independent Multi-Chamber Design

Equipped with three fully independent test chambers, this instrument allows simultaneous testing of up to three samples, which can be identical or different. This setup improves testing efficiency and flexibility, enabling labs to manage diverse testing needs with a single device.

Comprehensive Automated Control System

Featuring an intelligent one-touch operation system, this tester automates the entire process, from pressure control to test completion. Integrated software with data encryption ensures secure data handling, storage, and export, facilitating seamless data management and historical trend analysis.

Enhanced Customization and Safety Features

The tester is highly customizable, supporting specialized attachments for testing flammable, explosive, or toxic gases, along with GMP-compatible software options for industries with strict regulatory requirements. The system also offers robust self-diagnostic and data recovery functions to ensure continuous operation even under unexpected power outages.

Send us mail

Thanks for your inquiry, we will reply you within 12 Hours. Also you can add our WhatsApp for the quick reply.