Layer Interlayer Peeling Tester

Introduction of Layer Interlayer Peeling Tester

The interlayer bonding (internal bonding) strength of paperboard reflects its ability to resist layer separation, a critical property for materials like multi-layer paper and cardboard. The instrument accurately measures the interlayer peeling strength, allowing for precise control of interlayer bonding, which is crucial for products such as corrugated boards and heavy-duty paperboards. If internal bonding values are too low or uneven, problems may arise during printing with adhesive inks or in high-speed processes. Excessively high bonding strength, however, can complicate processing and increase costs. This tester is widely used in printing and packaging industries for testing materials like container boards, white paperboards, gray boards, and white cards. The product meets TAPPI-UM403 international standards and GB/T26203-2010 national standards.

Reference Standards

- GB/T 26203-2010: “Determination of Internal Bonding Strength of Paper and Paperboard (Scott Type)”

- TAPPI T569pm-00 and TAPPI T833pm-94

Detail Features About Layer Interlayer Peeling Tester

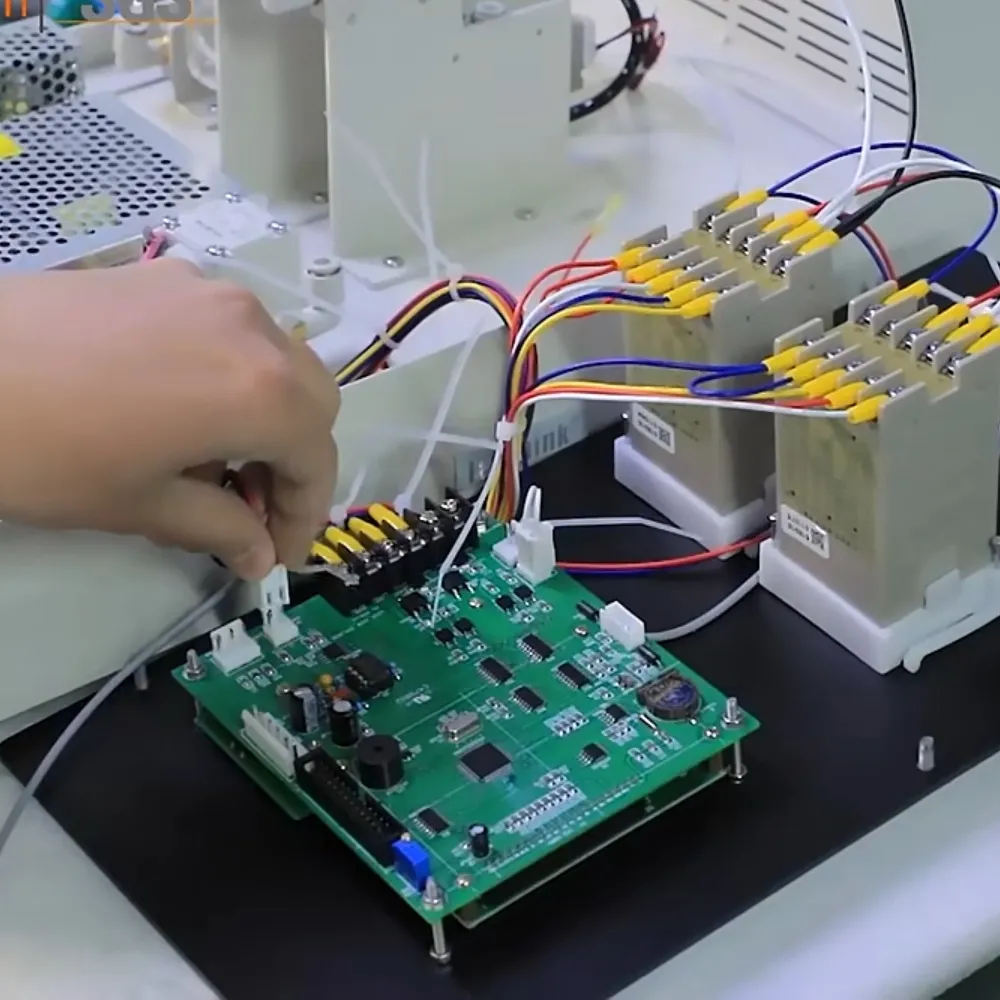

- Hydraulic Pressing: Utilizes hydraulic pressing for sample adhesion, with pressure that can be automatically adjusted.

- Microcomputer Control: Equipped with an LCD display in Chinese for data display, analysis, and statistical processing with print output.

Automation: Measures, calculates, and prints test results automatically

- Integrated Printer: Includes a modular one-piece printer for easy installation and low malfunction rates; both thermal and dot-matrix printers are available.

- Modern Design: The tester follows a compact, aesthetically pleasing design, facilitating ease of maintenance.

Technical Dates of Layer Interlayer Peeling Tester

Parameter |

Specification |

|---|---|

|

Measurement Range |

A: 250 ft.lb/1000.in²; B: 500 ft.lb/1000.in² |

|

Sample Size |

25.4 x 25.4 mm x five groups |

|

Sample Clamping Force |

Adjustable, 0–900 N |

|

Impact Angle |

90° |

|

Resolution |

0.001 lbf/in² |

Parameter |

Specification |

|---|---|

|

Measurement Error |

A: ±1; B: ±2 |

|

Units |

J/M², lbf/in² |

|

Power Supply |

AC220V, 50Hz, 0.3A |

|

Test Conditions |

Temperature: 10–30℃; Humidity ≤ 85% |

|

Main Unit Dimensions |

700 x 345 x 630 mm |

|

Net Weight |

Approx. 60 kg |

Invest in High Tech Lab Equipment

Enhance your business profitability with this advanced device

Advanced Differential Pressure Technology

Built on a highly accurate differential pressure testing principle, this gas permeability tester ensures reliable and precise measurements of gas transmission rates.

It is specifically engineered for a wide range of materials, making it versatile across industries for oxygen, carbon dioxide, nitrogen, and air permeability testing.

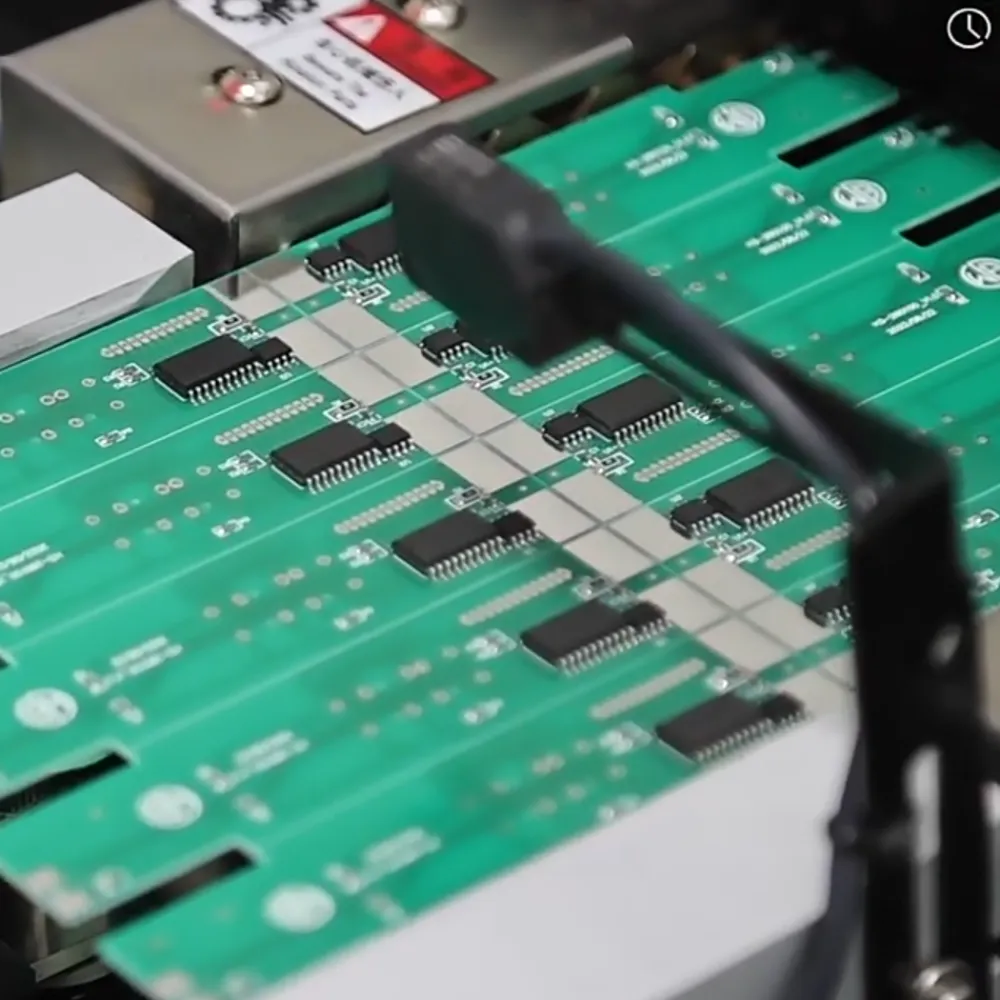

Independent Multi-Chamber Design

Equipped with three fully independent test chambers, this instrument allows simultaneous testing of up to three samples, which can be identical or different. This setup improves testing efficiency and flexibility, enabling labs to manage diverse testing needs with a single device.

Comprehensive Automated Control System

Featuring an intelligent one-touch operation system, this tester automates the entire process, from pressure control to test completion. Integrated software with data encryption ensures secure data handling, storage, and export, facilitating seamless data management and historical trend analysis.

Enhanced Customization and Safety Features

The tester is highly customizable, supporting specialized attachments for testing flammable, explosive, or toxic gases, along with GMP-compatible software options for industries with strict regulatory requirements. The system also offers robust self-diagnostic and data recovery functions to ensure continuous operation even under unexpected power outages.

Send us mail

Thanks for your inquiry, we will reply you within 12 Hours. Also you can add our WhatsApp for the quick reply.