Gas Permeability Tester

Introduction of Gas Permeability Tester

This product is a professional testing device based on the differential pressure testing principle, designed to measure gas transmission rates. It is suitable for testing the permeability of various gases such as O2, CO2, N2, and air through materials like plastic films, composite films, high-barrier materials, sheets, metal foils, and rubber.

Gas Permeability Test Method: Differential Pressure Method

Test methodology following: ISO 15105-1, ISO 2556, JIS K7126-1, ASTM D1434;

Recommended instrument model: G103, G101H, G101

This Tester can be used to test the gas transmission rates of O2, CO2, N2, and other gases.

Detail Features About Gas Permeability Tester

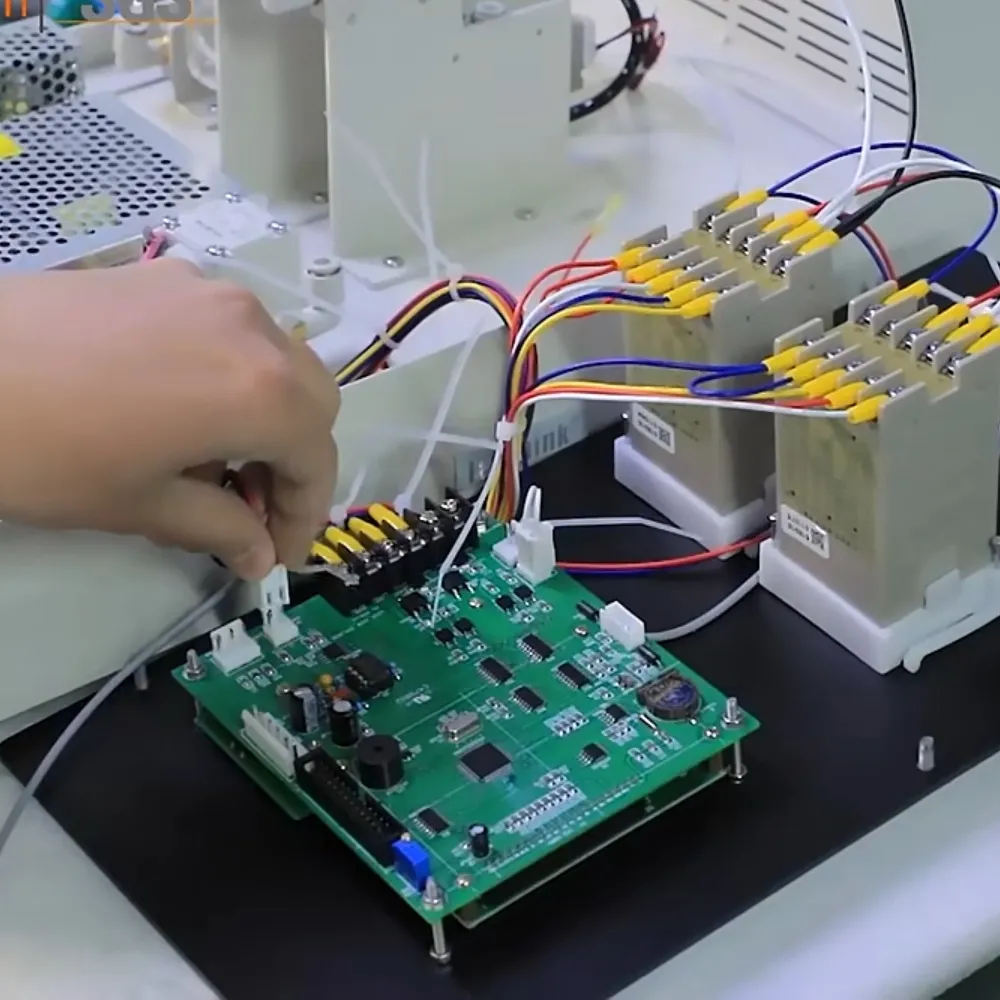

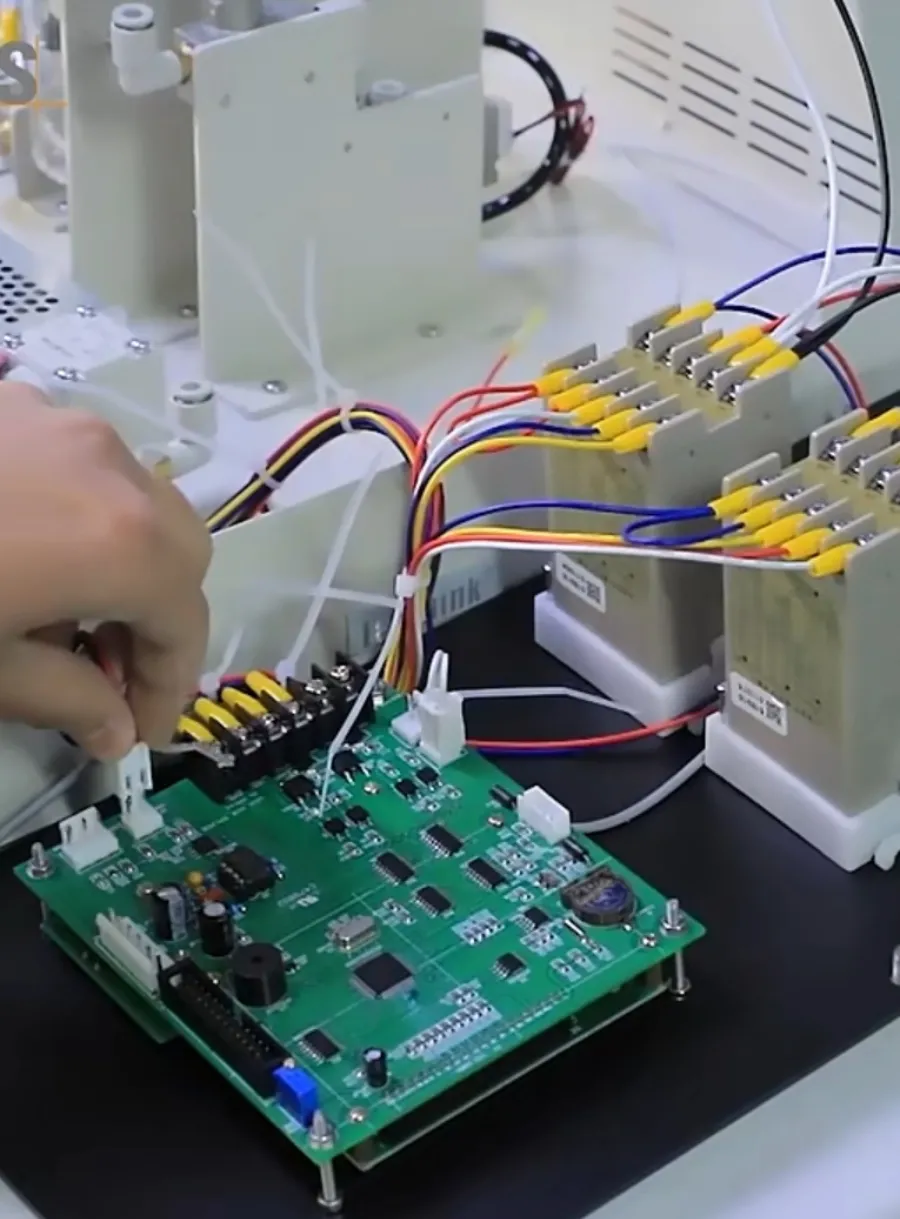

- Utilizes imported high-precision vacuum and pressure sensors for accurate pressure control and comprehensive process pressure maintenance.

- Capable of simultaneously determining gas transmission rate, solubility coefficient, and diffusion coefficient of the sample.

- Three fully independent test chambers enable simultaneous testing of three identical or different samples.

- One-touch operation with intelligent system control that automates the entire testing process.

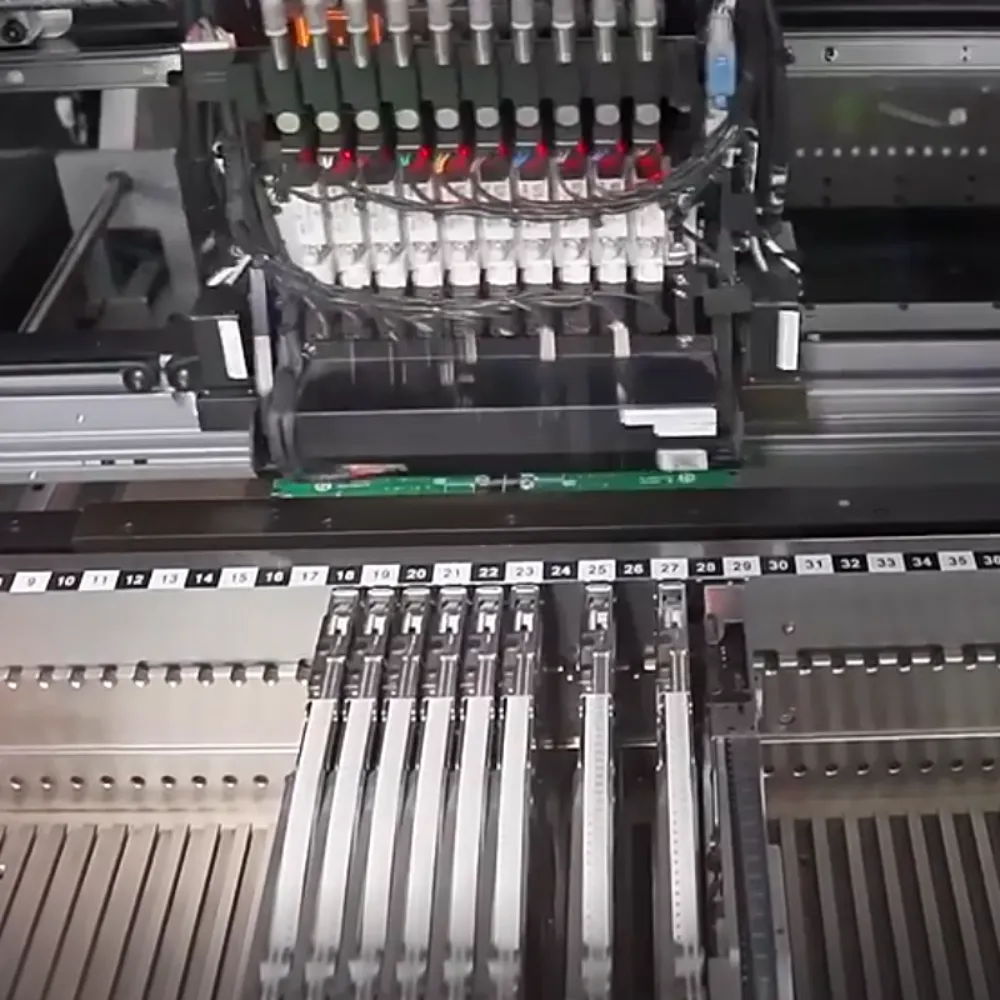

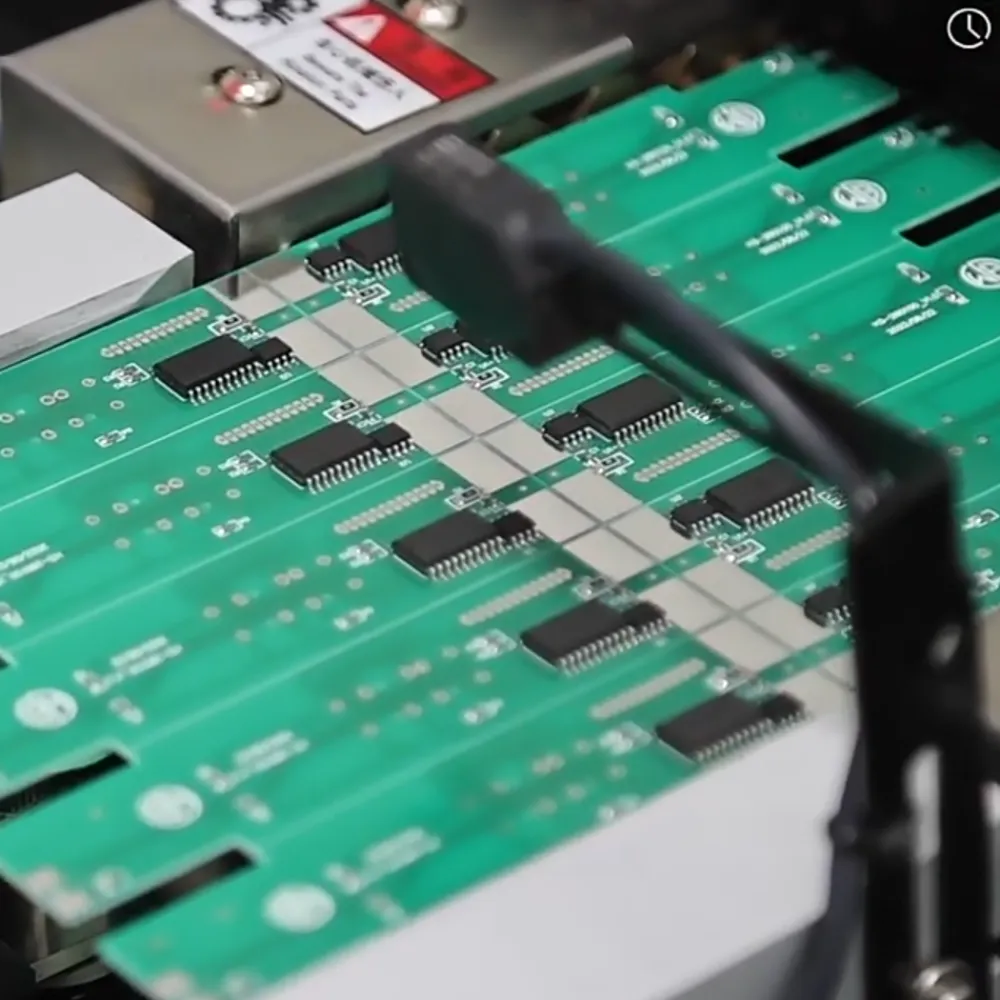

- Built with high-quality components to ensure the instrument’s stability and reliability.

- Automatic testing: set parameters, start testing, and the system automatically detects the end of the test and saves the results.

- Equipped with a standard membrane calibration function and external sensor calibration function for convenient equipment calibration.

- System includes self-diagnostic capabilities and data-saving features during power outages to protect data integrity.

- Wide-range, high-precision temperature, and humidity control to meet various test conditions.

- Multiple testing modes, including manual, proportional, and cycle, to accommodate various testing requirements.

- The test range can be extended as needed to support high-permeability testing requirements.

- Supports testing of toxic and flammable gases (requires modification).

- Provides standard membranes for quick calibration to ensure data accuracy and compatibility.

- Encrypted database system allows data export and functions for data storage, retrieval, and printing, facilitating product history analysis.

- Equipped with universal data interfaces like RS232 and USB for easy data transfer.

- Offers customized software, hardware, and special functions to meet user-specific needs for fixtures and software operations.

- Optional software compatible with China GMP data traceability standards, providing multi-level access management, audit tracking, electronic signatures, and a computerized system that fully meets pharmaceutical industry requirements.

Customizable to Industry Needs:

We support extensive customization options, including OEM, ODM, and OBM. Businesses can customize the device’s design, functionality, and branding to meet specific industry requirements. This flexibility ensures that the meter can be tailored to the unique demands of different meat processing and inspection applications.

Testing Principle of Gas Permeability Tester

Based on the differential pressure testing principle, the pre-treated sample is placed and clamped between the upper and lower test chambers. The lower chamber (low-pressure chamber) is vacuumed, followed by evacuating the entire system. Once the desired vacuum level is reached, the lower chamber is sealed, and the upper chamber (high-pressure chamber) is filled with the test gas at a specified pressure, creating a constant (adjustable) pressure differential across the sample. The gas permeates from the high-pressure side to the low-pressure side due to the pressure gradient. By monitoring the pressure in the low-pressure side, the barrier properties of the sample are determined.

Reference Standards:

GB/T 1038, ASTM D1434, ISO 2556, ISO 15105-1, JIS K7126-A, YBB 00082003, etc.

Testing Applications of Gas Permeability Tester

Basic Applications

- Film: Suitable for gas permeability testing of various plastic films, plastic composite films, paper-plastic composite films, coextrusion films, aluminized films, aluminum foil, and aluminum composite films.

- Sheet: Suitable for gas permeability testing of engineering plastics, rubber, building materials, etc., such as PP sheets, PVC sheets, PVDC sheets.

Extended Applications (requires special attachments or modifications)

- Flammable and Explosive Gases: Suitable for barrier testing of various films against flammable and explosive gases.

- Biodegradable Films: Suitable for gas permeability testing of biodegradable films, such as starch-based biodegradable bags.

- Paper and Cardboard: Suitable for gas permeability testing of paper and paper-plastic composite materials, such as cigarette aluminum foil paper, Tetra Pak sheets, instant noodle bowls, and disposable paper cups.

- Glass Fiber Cloth and Glass Fiber Paper: Suitable for gas permeability testing of materials like glass fiber cloth, glass fiber paper, such as Teflon-coated cloth, high-temperature Teflon cloth, and fluorosilicone cloth.

- Cosmetic Tube Sheets: Suitable for gas permeability testing of cosmetic tubes, aluminum-plastic tubes, and toothpaste tube sheets.

- Rubber Sheets: Suitable for gas permeability testing of various rubber sheets, such as vehicle tire permeability testing.

Technical Dates of Customized Gas Permeability Tester

Specification |

Parameter |

|---|---|

|

Test Range |

0.05 ~ 50.000 cm³/m²·24h·0.1MPa (standard) |

|

|

Upper limit not less than 500,000 cm³/m²·24h·0.1MPa (extended volume) |

|

Temperature Control Range |

5 ~ 95°C (water bath control)

|

|

Temperature Control Accuracy |

±0.1°C |

|

Vacuum Resolution |

0.1 Pa |

|

Vacuum Degree |

< 20 Pa |

|

Test Pressure |

-0.1 MPa~+0.1 MPa (standard) |

|

Note: Non-standard pressures customizable (maximum test pressure 1MPa) |

Specification |

Parameter |

|---|---|

|

Gas Source Pressure |

0.4 MPa~0.6 MPa |

|

Interface Size |

Ф6 mm polyurethane tube |

|

Dimensions |

765mm (L)×440mm (W)×470mm (H) |

|

Power Supply |

AC 220 V 50 Hz |

|

Net Weight |

Approx. 62 kg |

|

Test Gases |

O2, N2, CO2, etc. (gas source provided by user) |

|

|

CH4, H2, etc. flammable, explosive, and toxic gases (customizable, gas source provided by user)

|

|

Sample Quantity |

3 pieces (independent data) |

|

Sample Size |

Φ97 mm |

|

Sample Thickness |

≤ 5 mm

|

Product Configuration of Gas Permeability Tester

- Standard Configuration: Main unit, computer, professional software, vacuum pump, temperature controller, special sampler, vacuum grease, quick quantitative filter paper.

- Optional Accessories: Sampling blade, vacuum grease, vacuum pump oil, quick quantitative filter paper, humidity generator.

- Remarks: The gas inlet of the main unit uses a Ф6 mm polyurethane tube; gas source and distilled water are to be provided by the user.

Invest in High Tech Lab Equipment

Enhance your business profitability with this advanced device

Frequently Asked Question

The Customized meat Moisture meters should be calibrated regularly, depending on usage frequency and environmental conditions. For best results, it’s recommended to calibrate the device at least once a month or as specified in the user manual.

Yes, the meter is designed to measure moisture content in various types of meat, including beef, pork, chicken, lamb, and fish.

The device is designed to operate effectively in a variety of environmental conditions, making it suitable for use in processing plants, cold storage areas, and other industrial environments.

The meter primarily provides real-time measurements, data logging and storage features can be incorporated through customized support, enabling businesses to analyze and track moisture content trends over time.

Advanced Differential Pressure Technology

Built on a highly accurate differential pressure testing principle, this gas permeability tester ensures reliable and precise measurements of gas transmission rates.

It is specifically engineered for a wide range of materials, making it versatile across industries for oxygen, carbon dioxide, nitrogen, and air permeability testing.

Independent Multi-Chamber Design

Equipped with three fully independent test chambers, this instrument allows simultaneous testing of up to three samples, which can be identical or different. This setup improves testing efficiency and flexibility, enabling labs to manage diverse testing needs with a single device.

Comprehensive Automated Control System

Featuring an intelligent one-touch operation system, this tester automates the entire process, from pressure control to test completion. Integrated software with data encryption ensures secure data handling, storage, and export, facilitating seamless data management and historical trend analysis.

Enhanced Customization and Safety Features

The tester is highly customizable, supporting specialized attachments for testing flammable, explosive, or toxic gases, along with GMP-compatible software options for industries with strict regulatory requirements. The system also offers robust self-diagnostic and data recovery functions to ensure continuous operation even under unexpected power outages.

Send us mail

Thanks for your inquiry, we will reply you within 12 Hours. Also you can add our WhatsApp for the quick reply.