Five-Point Gradient Heat Sealer

Introduction of Heat Sealer

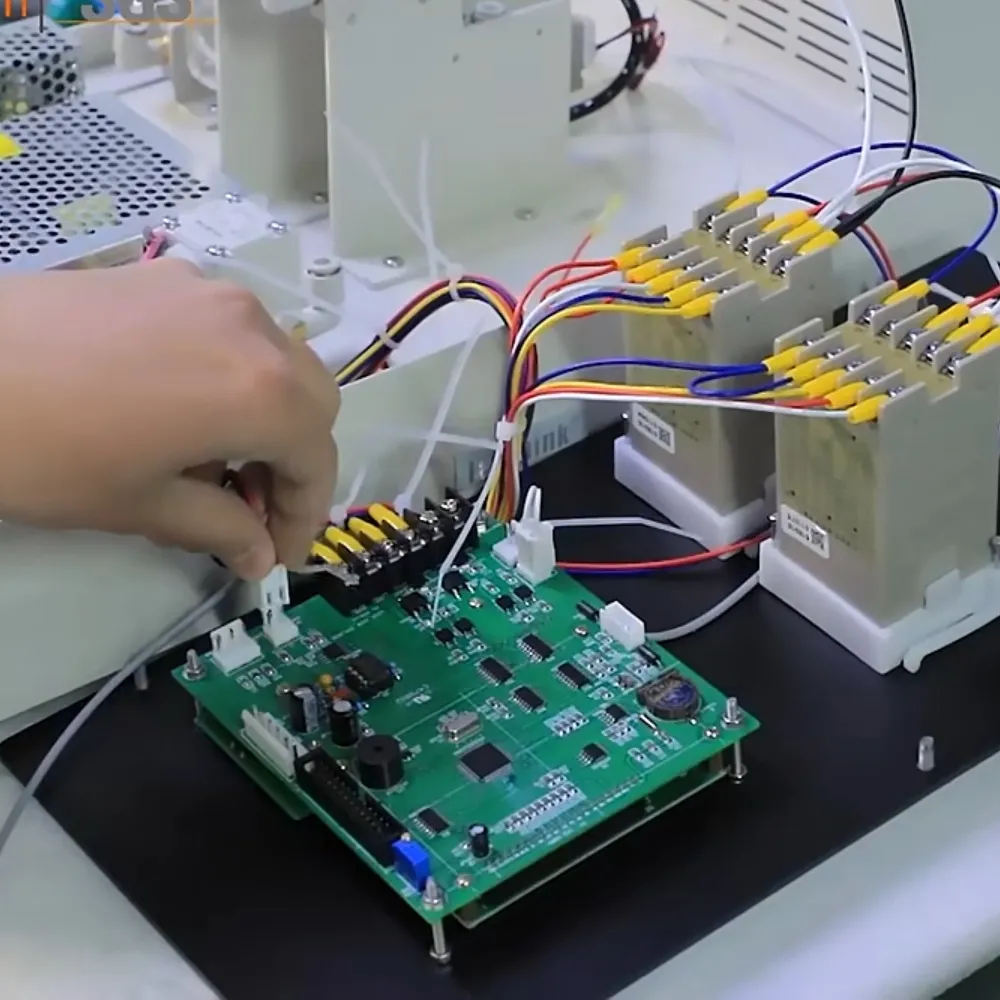

The Five-Point Gradient Heat Sealer uses a heat press sealing method to measure parameters such as sealing temperature, sealing time, and sealing pressure for plastic film substrates, flexible packaging composite films, coated paper, and other heat-sealing composite films. This device provides users with precise heat-sealing test indicators. Its control system is fully digital, featuring key components from internationally renowned brands, ensuring high automation and ease of operation.

Detail Features About heat sealer

- Digital display control system with fully automated operation.

- Digital P.I.D. temperature control with high accuracy in temperature regulation.

- Heat-sealing blade made of aluminum alloy for fast thermal conductivity and uniform sealing surface temperature.

- Custom-designed heating tube mold enables quick heating and extended service life.

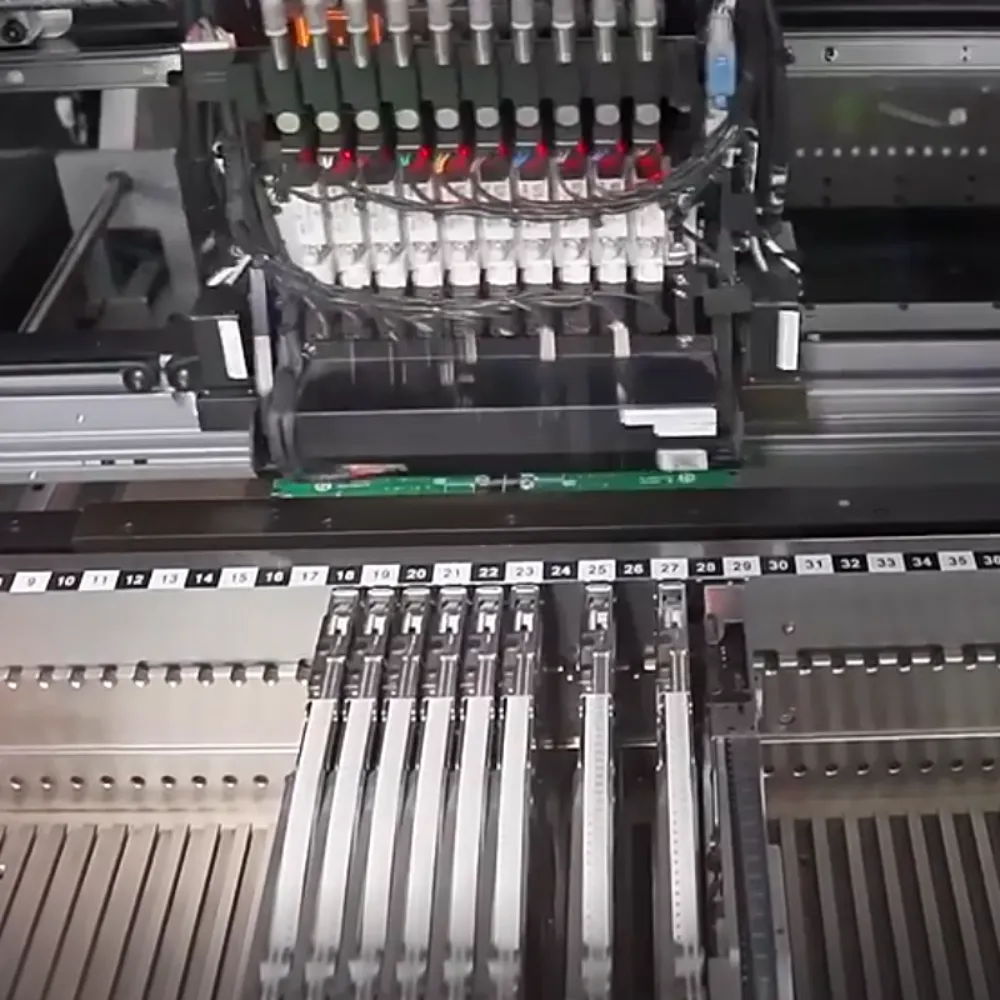

- Dual-cylinder structure with adjustable internal pressure balance mechanism ensures uniform blade movement left to right.

- High-precision pneumatic control components, sourced from internationally recognized brands.

- Burn protection and leakage protection designs enhance operational safety.

- Carefully designed heating elements for prolonged equipment lifespan.

- Two operational modes (automatic and manual) for efficient functionality.

- Ergonomically optimized operation panel for user convenience.

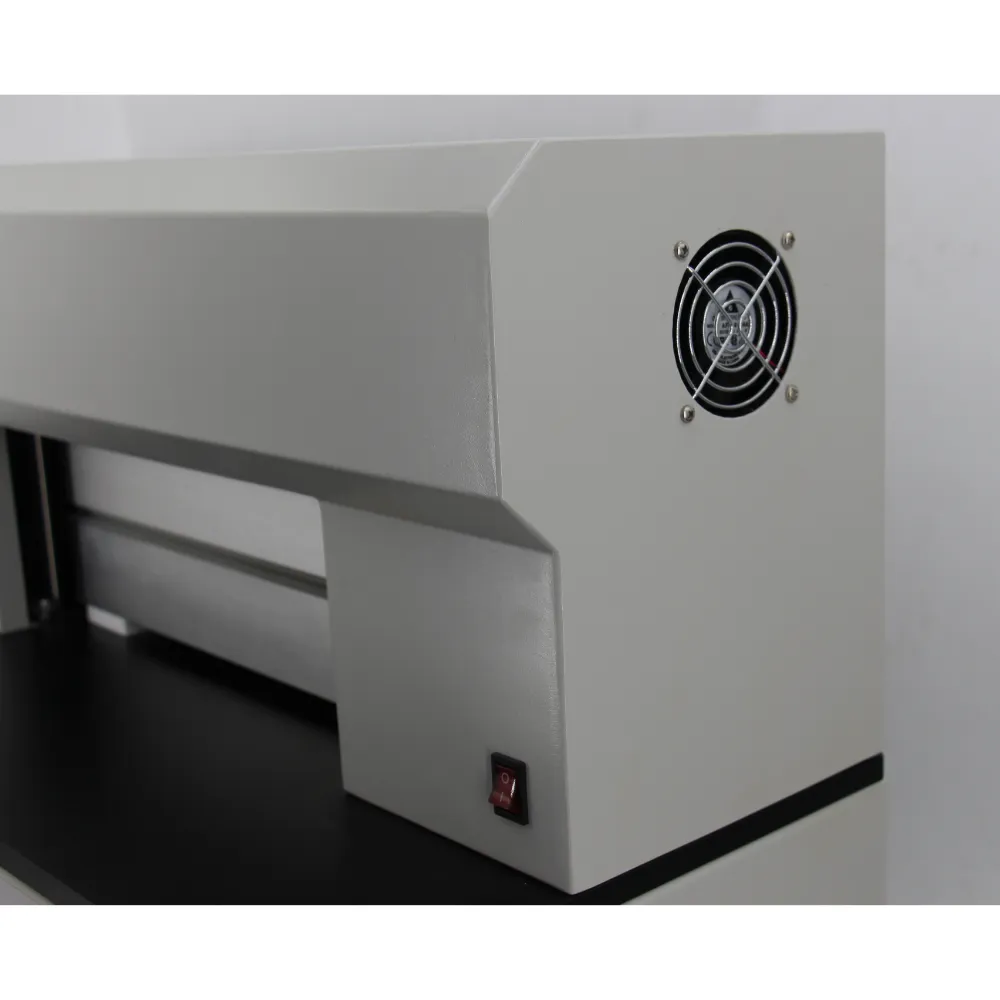

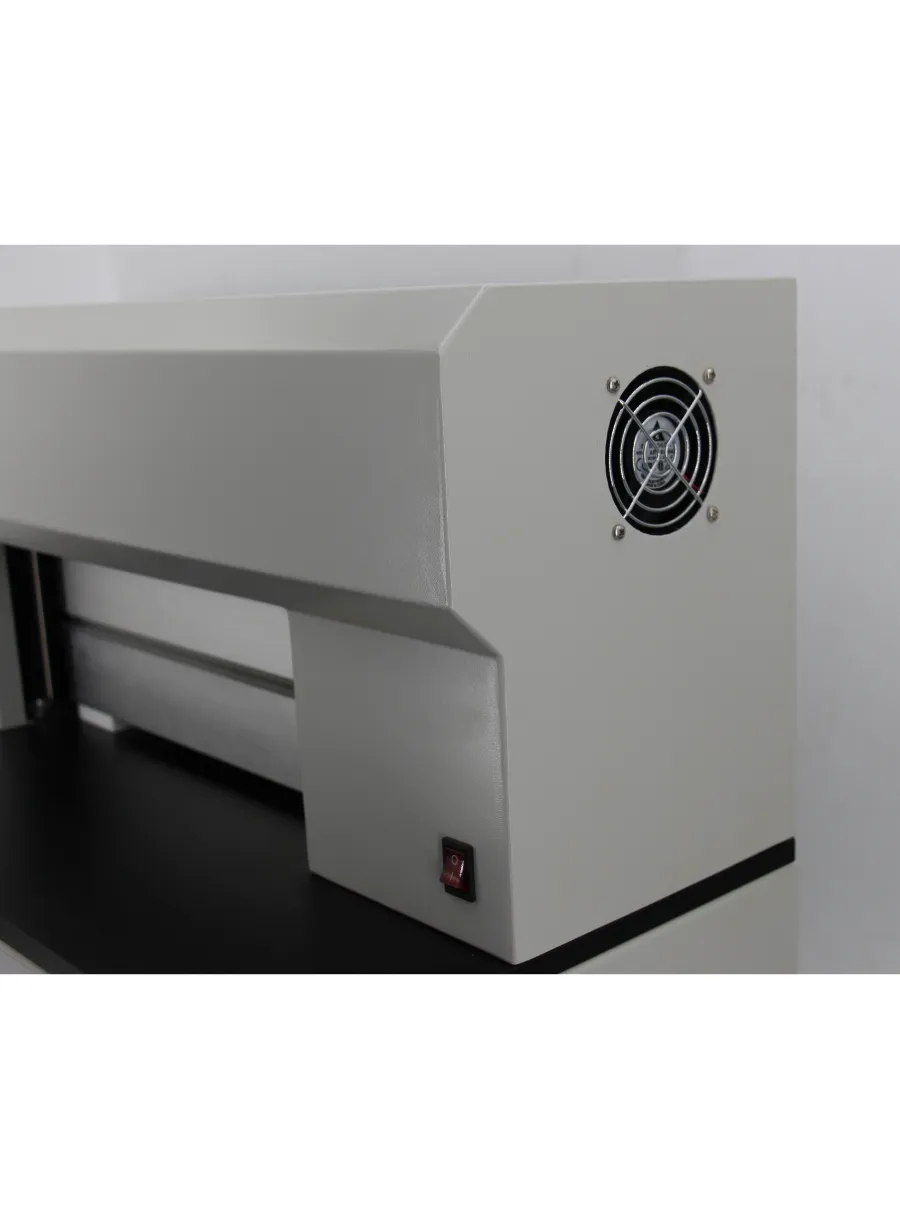

- Dual side-mounted cooling fans for uniform and rapid heat dissipation.

Built-in cooling fans on both sides

Built-in cooling fans on both sides: better heat dissipation, improved machine performance and extended machine life

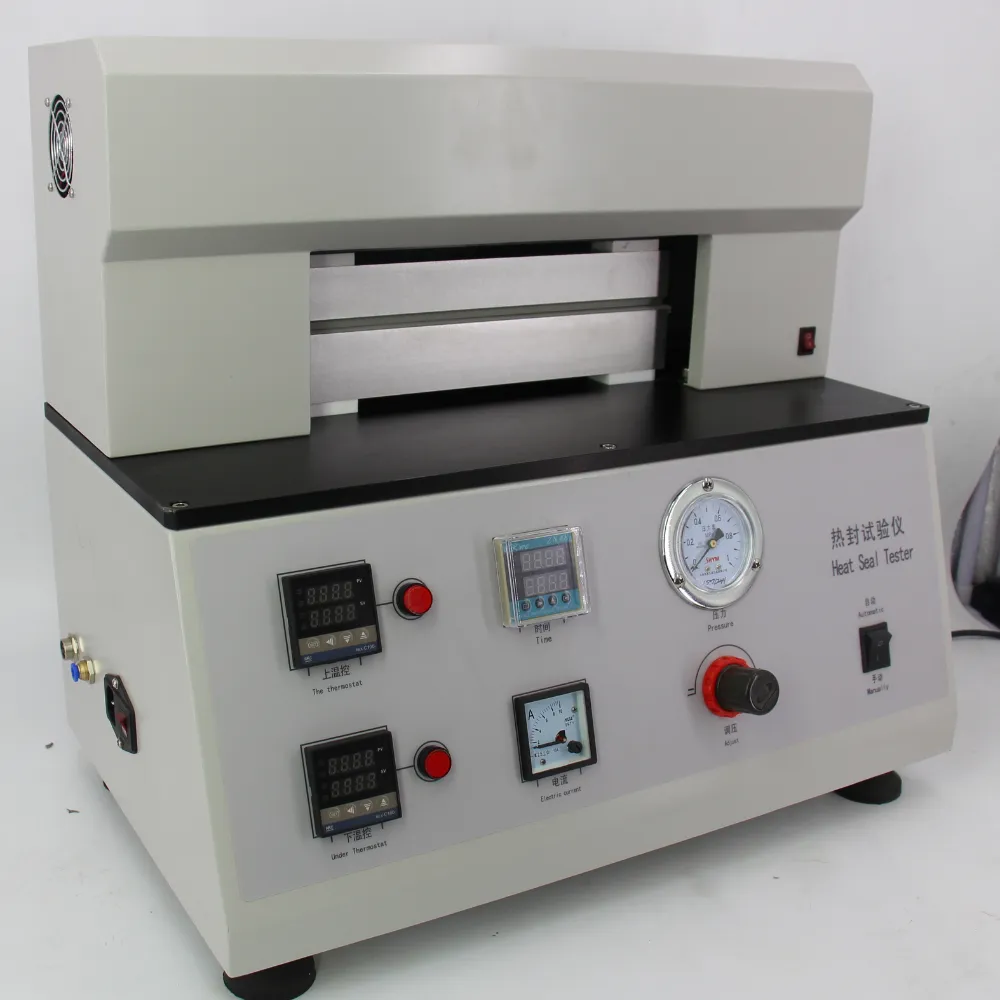

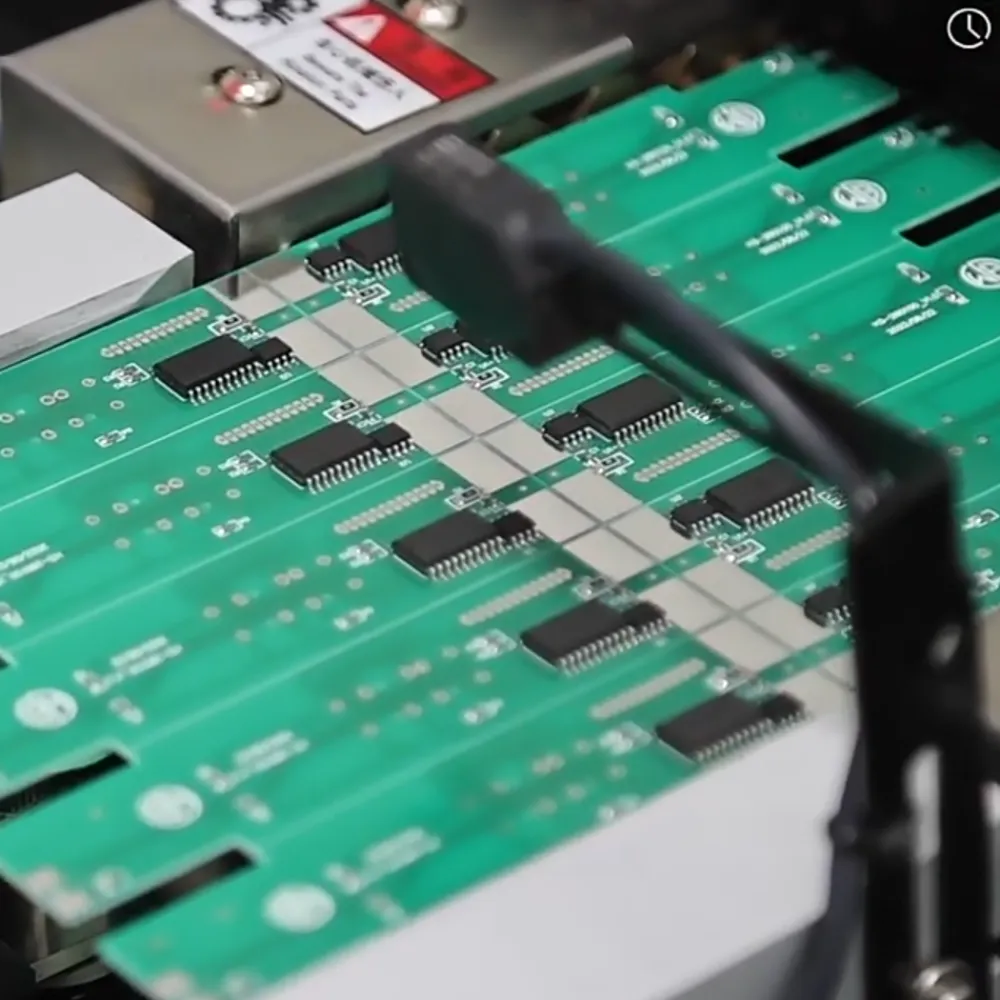

Upper and lower sealing knives:

Upper and lower sealing knives: heat sealing is faster, greatly improving the efficiency of operation, saving time and labor.

Technical Dates of Customized heat sealer

Specification |

Parameter |

|---|---|

|

Power Voltage |

AC220V 50HZ |

|

Sealing Temperature |

Room Temperature +10 to 250°C |

|

Temperature Control Accuracy |

±1°C |

|

Sealing Pressure |

Adjustable range 0 to 0.7 MPa |

|

Sealing Time |

Adjustable range 0.01 to 9999.99 seconds |

|

Sealing Area |

40mm × 10mm × 5 points (custom sizes available) |

|

Heating Mode |

Single or dual heating; upper and lower blades can be controlled separately |

|

Testing Mode |

Manual mode / Automatic mode |

|

(Manual mode via foot pedal, automatic mode via adjustable delay relay) |

Specification |

Parameter |

|---|---|

|

Air Source Pressure |

≤0.7 MPa (provided by user) |

|

Testing Conditions |

Standard laboratory environment |

|

Main Unit Dimensions |

550mm × 330mm × 460mm (L × W × H) |

|

Net Weight |

Approx. 35 kg |

|

Standards Compliant |

QB/T 2358, ASTM F2029, YBB 00122003, etc. |

|

Standard Configuration |

Main unit + foot pedal switch + air hose + air filter + power cord + technical documentation |

Invest in High Tech Lab Equipment

Enhance your business profitability with this advanced device

Frequently Asked Question

The Five-Point Gradient Heat Sealer is designed to test plastic film substrates, flexible packaging composite films, coated paper, and other heat-sealing composite films. It can measure parameters like sealing temperature, time, and pressure across a wide range of materials commonly used in packaging and industrial applications.

This machine uses digital P.I.D. temperature control, achieving an accuracy of ±1°C. This high level of precision helps ensure consistent sealing quality, making it reliable for various professional and laboratory applications.

Yes, the heat sealer offers both manual and automatic modes for flexible operation. In manual mode, the foot pedal controls the process, while in automatic mode, an adjustable delay relay provides hands-free, efficient operation for repetitive tasks.

The dual side-mounted cooling fans enhance heat dissipation, allowing for even and rapid cooling of the device. This feature improves operational safety and ensures the machine maintains a stable temperature for high-performance sealing results.

Advanced Differential Pressure Technology

Built on a highly accurate differential pressure testing principle, this gas permeability tester ensures reliable and precise measurements of gas transmission rates.

It is specifically engineered for a wide range of materials, making it versatile across industries for oxygen, carbon dioxide, nitrogen, and air permeability testing.

Independent Multi-Chamber Design

Equipped with three fully independent test chambers, this instrument allows simultaneous testing of up to three samples, which can be identical or different. This setup improves testing efficiency and flexibility, enabling labs to manage diverse testing needs with a single device.

Comprehensive Automated Control System

Featuring an intelligent one-touch operation system, this tester automates the entire process, from pressure control to test completion. Integrated software with data encryption ensures secure data handling, storage, and export, facilitating seamless data management and historical trend analysis.

Enhanced Customization and Safety Features

The tester is highly customizable, supporting specialized attachments for testing flammable, explosive, or toxic gases, along with GMP-compatible software options for industries with strict regulatory requirements. The system also offers robust self-diagnostic and data recovery functions to ensure continuous operation even under unexpected power outages.

Send us mail

Thanks for your inquiry, we will reply you within 12 Hours. Also you can add our WhatsApp for the quick reply.