Hydraulic Universal Testing Machine

Introduction of Hydraulic Universal Testing Machine

Microcomputer Display-Controlled Hydraulic Universal Testing Machine is designed mainly for tensile, compression, bending, and shearing tests on metallic materials. With the addition of specific attachments, it is also capable of testing wood, cement, concrete, rubber, and related products. The machine’s main unit employs an upper-cylinder structure, where the tensile testing area is located below the main body and the compression/bending area is between the upper cylinder base and lower grip. Adjustments to the tensile space are made by moving the lower grip seat. The force measurement system uses sensors, and the machine operates via an independently developed microcomputer display system, which can show test force, peak values, deformation, and various test curves. It can also print custom test reports or allow users to edit report formats.

Detail Features About Hydraulic Universal Testing Machine

Main Features About Universal Testing Machine

Manual Hydraulic Control: The testing machine uses a manually controlled hydraulic valve to drive a precision hydraulic cylinder, allowing manual control over test force, displacement, and deformation in various modes to conduct tensile, compression, bending, and flexural tests. It meets the basic requirements of GB/T 228-2002 “Metal Materials Room Temperature Tensile Testing Method”.

Manual Hydraulic Control: The testing machine uses a manually controlled hydraulic valve to drive a precision hydraulic cylinder, allowing manual control over test force, displacement, and deformation in various modes to conduct tensile, compression, bending, and flexural tests. It meets the basic requirements of GB/T 228-2002 “Metal Materials Room Temperature Tensile Testing Method”.

Dedicated Software: Windows-based software supports tests according to national or user-supplied standards, measuring the performance parameters of various materials. The software provides data analysis, reporting, and curve display functions, with options for curve enlargement, comparison, and traversal, making it intelligent and user-friendly.

Robust Test Database: The system includes a built-in test database for easy storage, retrieval, and review of test data.

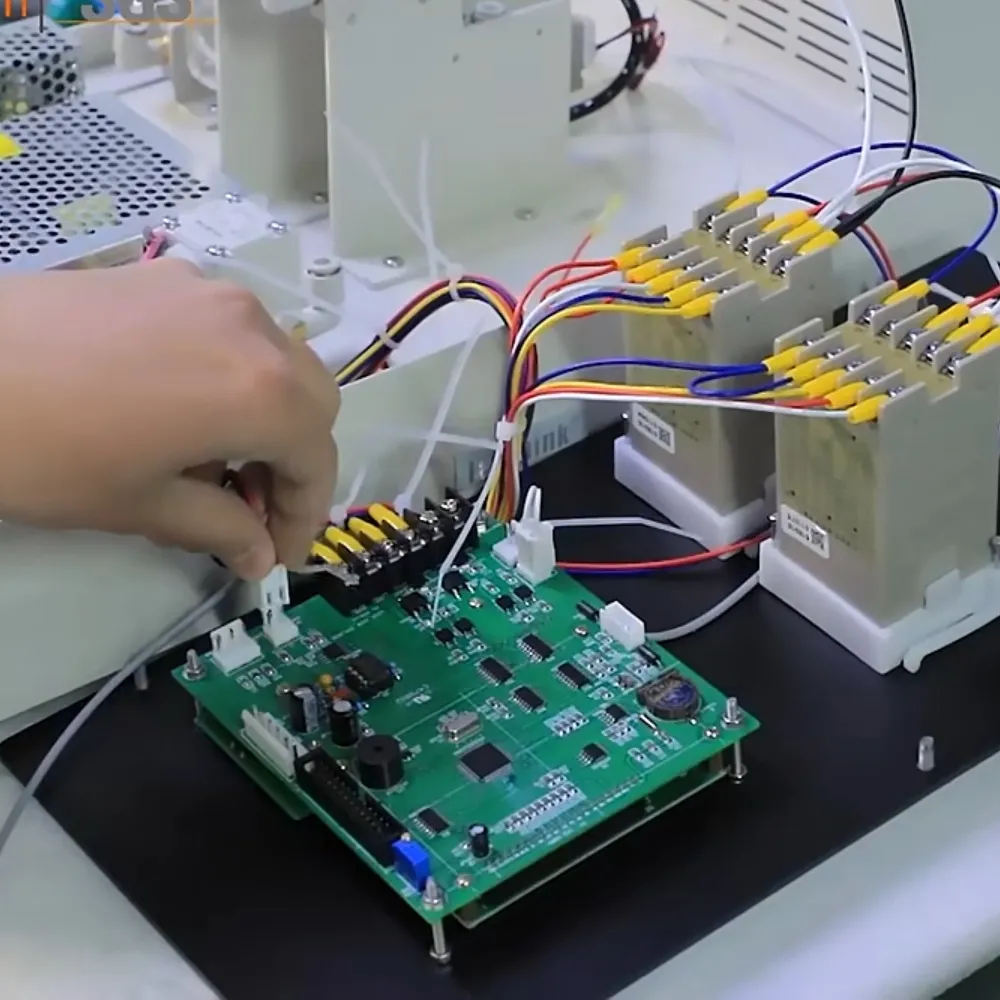

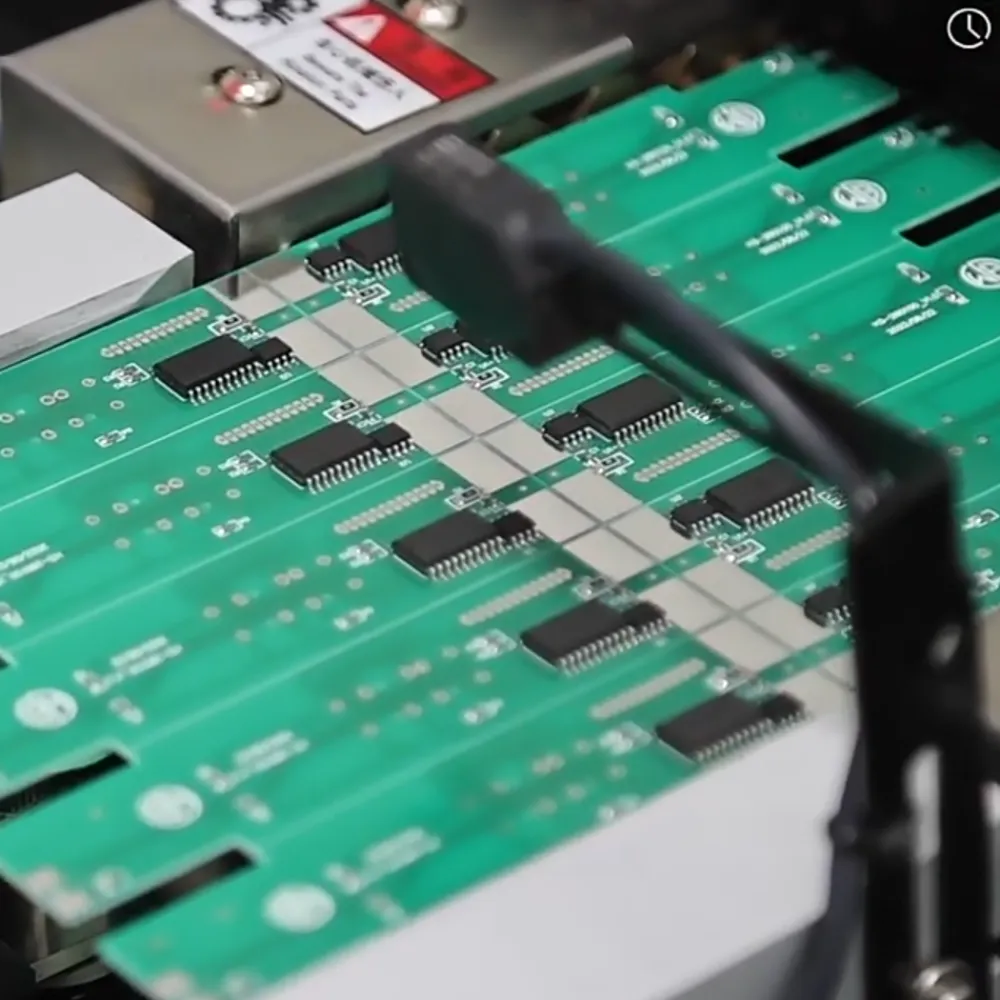

High-Precision Amplifier: Features a 4-range measurement for testing force with automatic switching, providing stable and reliable accuracy.

Advanced Self-Inspection and Protection: The system is equipped with robust self-checking capabilities and comprehensive protection features.

Software Interface of Universal Testing Machine

Technical Dates of Universal Testing Machine

Parameter |

Specification |

|---|---|

|

Max Testing Force |

600 kN (60T)/1000 KN(100T) |

|

Test Force Accuracy |

≤ ±1% |

|

Test Force Measurement Range |

2%–100% of maximum force |

|

Constant Stress Control Range |

2–60 N/mm²·S⁻¹ |

|

Constant Strain Control Range |

0.00025/s–0.0025/s |

|

Constant Displacement Control Range |

0.5–50 mm/min |

|

Clamping Method |

Hydraulic clamping |

|

Round Sample Diameter Range |

Φ10–Φ60 |

|

Flat Sample Thickness Range |

0–55 mm |

|

Flat Sample Width |

80 mm

|

|

Max. Tensile Test Space |

640 mm |

|

Max. Compression Test Space |

600 mm |

Parameter |

Specification |

|---|---|

|

Control Cabinet Dimensions |

1200 × 620 × 850 mm |

|

Main Unit Dimensions |

910 × 740 × 2200 mm |

|

Machine Power |

2.5 kW |

|

Main Unit Weight |

2000 kg |

|

Column Clearance |

580 mm |

|

Compression Plate Diameter |

Φ160 |

|

Bending Support Span |

400 mm |

|

Bending Support Width |

140 mm |

|

Max. Piston Stroke |

200 mm |

|

Maximum Bending Allowance |

100 mm

|

|

Max. Piston Speed |

Approx. 80 mm/min |

|

Test Space Adjustment Speed |

Approx. 150 mm/min

|

Product Configuration of Universal Testing Machine

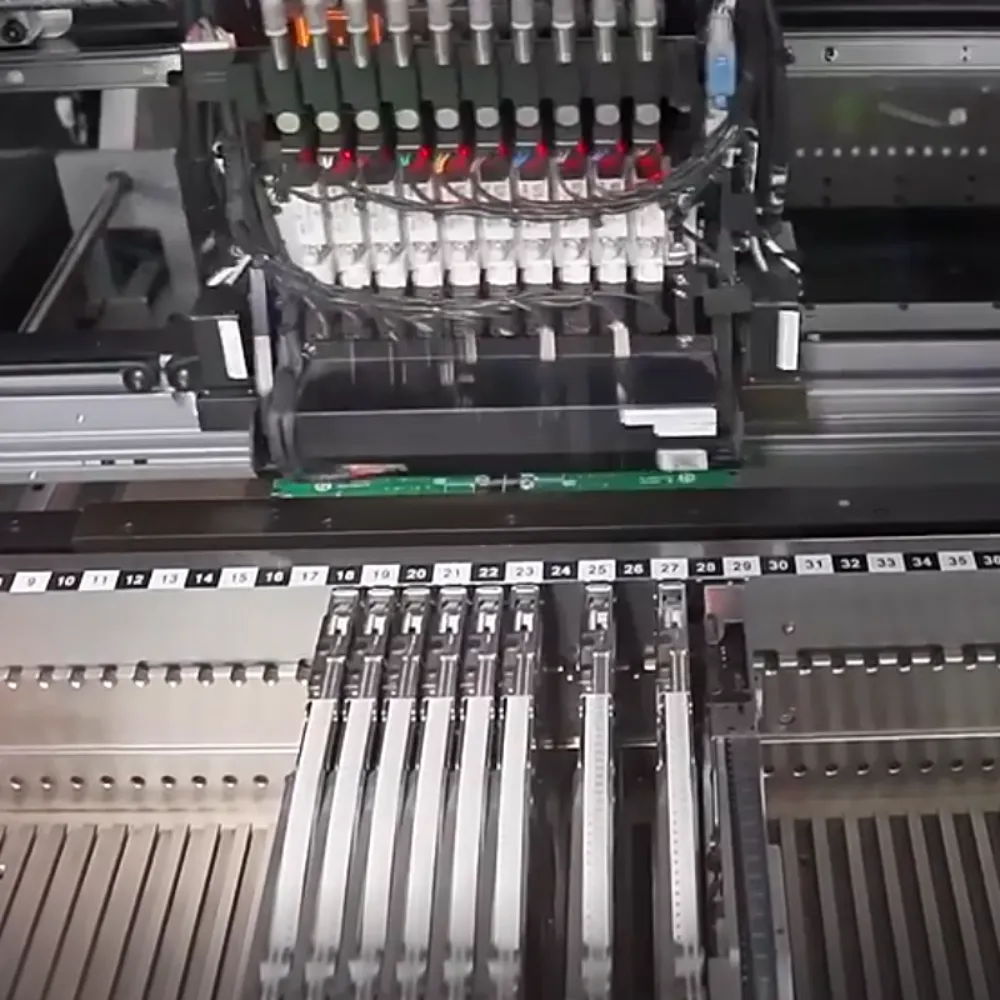

- Main Unit: Equipped with two lead screws, four columns, bottom cylinder, chain drive, hydraulic clamping, microcomputer display, manual valve control, standard three sets of grips, 160 mm compression plate (without bending fixture or extensometer).

- Desktop Computer: For test control and data management.

- Desktop Printer: For report printing.

- Hydraulic Control Cabinet: Includes hydraulic control system for test operations.

Invest in High Tech Lab Equipment

Enhance your business profitability with this advanced device

Frequently Asked Question

The WDW Series is versatile, capable of performing various mechanical tests such as tension, compression, bending, and shearing on diverse materials. It is suited for metals, plastics, rubber, textiles, and composite materials, making it ideal for industries like automotive, aerospace, construction, and manufacturing. The machine’s multi-functional clamps and accessories enable it to adapt to different testing scenarios, from standard tensile tests to complex cyclic tests.

The WDW Series is equipped with a computer-controlled AC servo motor, providing precise control over parameters like loading force and displacement. This automation ensures high accuracy in measurement and repeatability. The system also allows real-time data visualization and analysis, simplifying the test process and minimizing manual errors, which is essential for research and quality control environments.

This machine complies with various international testing standards, including ISO, ASTM, JIS, and BS. Compliance ensures that the results are globally recognized and compatible with industry norms, making the machine suitable for both commercial and regulatory testing needs.

The WDW Series offers several connectivity options, including USB, PCI, and RS232. This flexibility allows seamless integration with existing laboratory information systems and easy data export for further analysis, report generation, or remote monitoring of tests.

Advanced Differential Pressure Technology

Built on a highly accurate differential pressure testing principle, this gas permeability tester ensures reliable and precise measurements of gas transmission rates.

It is specifically engineered for a wide range of materials, making it versatile across industries for oxygen, carbon dioxide, nitrogen, and air permeability testing.

Independent Multi-Chamber Design

Equipped with three fully independent test chambers, this instrument allows simultaneous testing of up to three samples, which can be identical or different. This setup improves testing efficiency and flexibility, enabling labs to manage diverse testing needs with a single device.

Comprehensive Automated Control System

Featuring an intelligent one-touch operation system, this tester automates the entire process, from pressure control to test completion. Integrated software with data encryption ensures secure data handling, storage, and export, facilitating seamless data management and historical trend analysis.

Enhanced Customization and Safety Features

The tester is highly customizable, supporting specialized attachments for testing flammable, explosive, or toxic gases, along with GMP-compatible software options for industries with strict regulatory requirements. The system also offers robust self-diagnostic and data recovery functions to ensure continuous operation even under unexpected power outages.

Send us mail

Thanks for your inquiry, we will reply you within 12 Hours. Also you can add our WhatsApp for the quick reply.