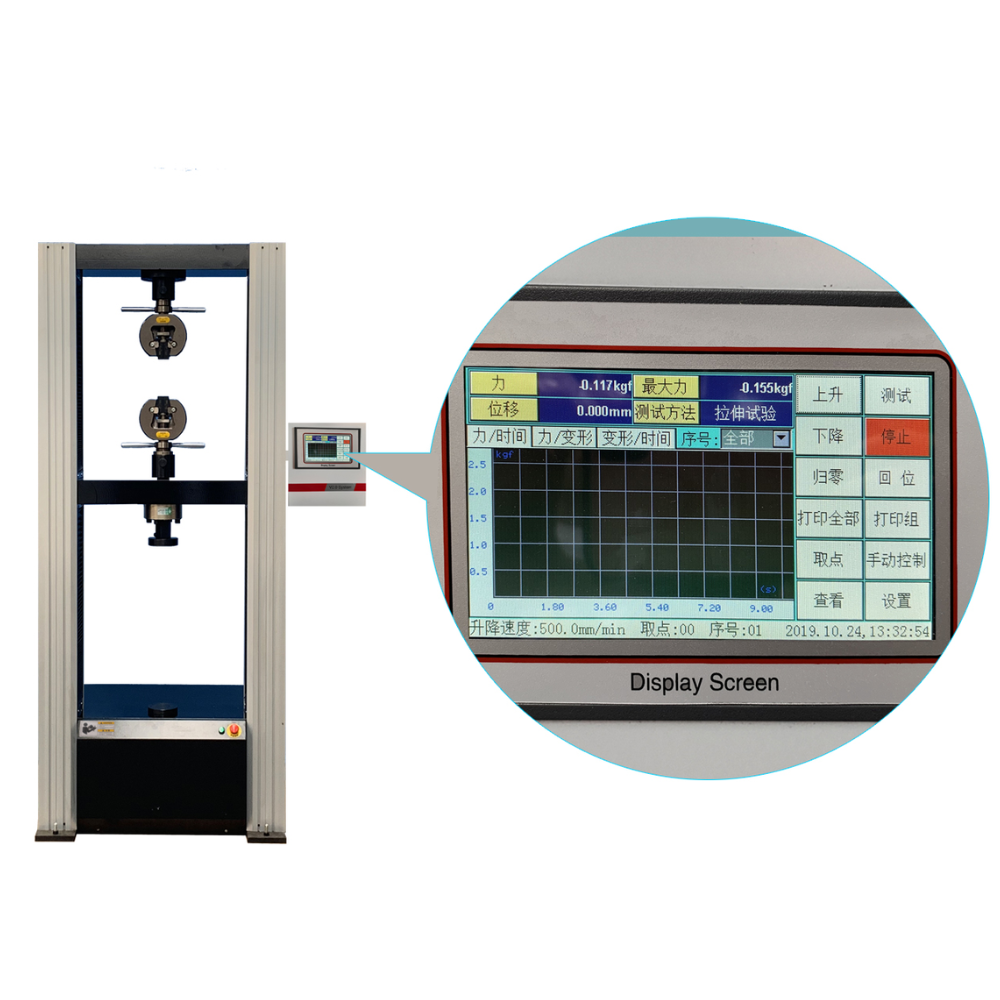

Touch Screen Universal Testing Machine

Introduction of Touch Screen Universal Testing Machine

WDL Series Universal Testing Machine incorporates advanced control technology and design inspired by high-end international testing equipment. Its appearance is sleek, user-friendly, and the machine boasts stable, reliable performance. Equipped with a fully digital motor speed system and a high-precision drive mechanism with an arc synchronous belt and reducer, it drives the precise ball screw for loading. The machine is pollution-free, low-noise, and highly efficient with a broad speed regulation range. Suitable for testing the mechanical properties of various metals, non-metals, and composites, it meets all relevant national standards.

We can provide 1T, 3T, 5T, 10T, 30T, 60T, 100T Microcomputer-Controlled Electronic Tensile Testing Machine or as your need.

Detail Features About Universal Testing Machine

- Single-Arm Design: Features a single-arm frame with a three-column structure surrounding a ball screw, providing robust rigidity, high precision, and long service life.

- High-Precision Digital Control: Equipped with a high-precision digital speed and reducer system, driving the ball screw for a broad range of testing speeds.

- Stable and Reliable Performance: Ensures high rigidity, precision, low noise, and smooth operation.

- Versatile Testing Functions: Allows tensile, compression, peel, tear, and bending tests through controlled motor-driven ball screws for precise beam movement.

Specification |

Parameter |

|---|---|

|

Compression Stroke |

750 mm (excluding grips) |

|

Power Supply |

220V AC, 50Hz |

|

Machine Power |

1.0 KW |

|

Working Environment |

Room temperature to 40°C, 20%–80% humidity |

|

Software Interface |

Chinese application software on Windows 7 |

|

Dimensions |

720 × 550 × 1800 mm (approx.) |

|

Weight |

260 kg (approx.) |

Applicable Standards of Universal Testing Machine

FTS Precision Testing System employs a high-precision microcontroller as the main control unit, handling test setup, machine control, data acquisition, processing, display, and printing of test results. A dedicated Windows XP, Win7, or Win8-based intelligent software package is available, supporting measurement and evaluation of test parameters in compliance with national and international standards. Test data is processed, reported, and visualized in customized formats.

Automatic Functions of Universal Testing Machine

Feature |

Description |

|---|---|

|

Automatic Zeroing |

Automatically zeroes the measurement system upon receiving the test start command. |

|

Automatic Return |

Recognizes sample breakage and automatically returns the moving crosshead to its initial position. |

|

Automatic Range Adjustment |

Automatically switches to the appropriate load range based on the load, ensuring measurement accuracy. |

|

Auto Data Saving |

Automatically saves test data and conditions to prevent data loss due to power outages or unsaved changes. |

|

Auto Speed Adjustment |

Allows automatic or manual crosshead speed adjustment during testing as per preset programs. |

|

Automatic Calibration |

Automatically calibrates accuracy of displayed values. |

|

Test Process Automation |

Complete test process including measurement, display, and analysis is handled by the microcomputer. |

Feature |

Description |

|---|---|

|

Test Software |

Flat user interface with menu prompts and easy mouse selection for convenient operation. |

|

Dynamic Display |

Real-time data and curve display during testing. |

|

Result Reproduction |

Enables retrieval and reanalysis of test results and curves. |

|

Curve Traversal |

Allows pinpointing of load and deformation data points on test curves for parameter analysis. |

|

Comparison Analysis |

Supports overlaying multiple sample curves with different colors, zooming for detailed analysis (with optional computer). |

|

Curve Selection |

Allows choice of stress-strain or force-displacement curves for display and printing. |

|

Batch Testing |

Enables sequential testing of samples with identical parameters after a single setup. |

|

Customizable Reports |

Supports user-specific formatting for test report programming and printing. |

Software Interface of Universal Testing Machine

Technical Dates of Universal Testing Machine

Specification |

Parameter |

|---|---|

|

Max Testing Force |

5000N (Optional: 500, 2000, 3000N) |

|

Test Machine Accuracy |

Class 0.5 |

|

Force Measurement Range |

0.2%—100% F.S |

|

Indication Error |

≤ ±1% |

|

Force Resolution |

1/300000, constant throughout the entire range |

|

Displacement Rate Adjustment |

0.1–500 mm/min |

|

Tensile Stroke |

750 mm (with fixture) |

|

Safety Protection |

Electronic limit protection |

Specification |

Parameter |

|---|---|

|

Power Supply and Voltage |

AC 220V, 50Hz |

|

Power Consumption |

0.6kW |

|

Operating Environment |

Ambient temperature to 40°C, 20%–80% humidity |

|

Software and Interface |

Multilingual application software |

|

Dimensions |

480×480×1400 mm (approx.) |

|

Weight |

80kg (approx.) |

Product Configuration of Universal Testing Machine

Component |

Quantity |

|---|---|

|

Testing Machine Main Frame |

1 set |

|

Servo Motor |

1 set |

|

Drive System |

1 set |

|

High-Precision Load Sensor |

1 unit |

|

High-Precision Ball Screw |

1 pair |

|

Precision Deceleration System |

1 set |

|

Precision Testing System |

1 set |

|

Touchscreen Display |

1 set |

|

Tensile Fixture |

1 set |

|

Compression Accessories |

Optional, 1 set |

|

Technical Documentation |

1 set including user manuals, software guide, certification, and packing list. |

Invest in High Tech Lab Equipment

Enhance your business profitability with this advanced device

Frequently Asked Question

The WDW Series is versatile, capable of performing various mechanical tests such as tension, compression, bending, and shearing on diverse materials. It is suited for metals, plastics, rubber, textiles, and composite materials, making it ideal for industries like automotive, aerospace, construction, and manufacturing. The machine’s multi-functional clamps and accessories enable it to adapt to different testing scenarios, from standard tensile tests to complex cyclic tests.

The WDW Series is equipped with a computer-controlled AC servo motor, providing precise control over parameters like loading force and displacement. This automation ensures high accuracy in measurement and repeatability. The system also allows real-time data visualization and analysis, simplifying the test process and minimizing manual errors, which is essential for research and quality control environments.

This machine complies with various international testing standards, including ISO, ASTM, JIS, and BS. Compliance ensures that the results are globally recognized and compatible with industry norms, making the machine suitable for both commercial and regulatory testing needs.

The WDW Series offers several connectivity options, including USB, PCI, and RS232. This flexibility allows seamless integration with existing laboratory information systems and easy data export for further analysis, report generation, or remote monitoring of tests.

Advanced Differential Pressure Technology

Built on a highly accurate differential pressure testing principle, this gas permeability tester ensures reliable and precise measurements of gas transmission rates.

It is specifically engineered for a wide range of materials, making it versatile across industries for oxygen, carbon dioxide, nitrogen, and air permeability testing.

Independent Multi-Chamber Design

Equipped with three fully independent test chambers, this instrument allows simultaneous testing of up to three samples, which can be identical or different. This setup improves testing efficiency and flexibility, enabling labs to manage diverse testing needs with a single device.

Comprehensive Automated Control System

Featuring an intelligent one-touch operation system, this tester automates the entire process, from pressure control to test completion. Integrated software with data encryption ensures secure data handling, storage, and export, facilitating seamless data management and historical trend analysis.

Enhanced Customization and Safety Features

The tester is highly customizable, supporting specialized attachments for testing flammable, explosive, or toxic gases, along with GMP-compatible software options for industries with strict regulatory requirements. The system also offers robust self-diagnostic and data recovery functions to ensure continuous operation even under unexpected power outages.

Send us mail

Thanks for your inquiry, we will reply you within 12 Hours. Also you can add our WhatsApp for the quick reply.