Universal Testing Machine

Introduction of Universal Testing Machine

Computer-Controlled Electronic Universal Testing Machine features an elegant design, user-friendly operation, and reliable, stable performance. A computer-controlled speed regulation system drives the AC servo motor, which, after deceleration, uses a precision ball screw mechanism to move the crossbeam up and down. This machine performs tensile, compression, bending, and shearing tests on metal and non-metal samples and automatically calculates parameters such as tensile strength, upper and lower yield strength, elongation, non-proportional elongation strength (ReH, ReL, Rp0.2, Fm, Rt0.5, Rm, E), among others. Tests and data are provided according to GB, ISO, DIN, ASTM, JIS, and other international standards. This equipment operates quietly, efficiently, with no pollution, featuring a wide speed adjustment range and extensive crossbeam travel distance. It is ideal for industries like steel, sheet metals, alloys, non-metal materials, quality inspection institutions, and research laboratories.

We can provide 1T, 3T, 5T, 10T, 30T, 60T, 100T Microcomputer-Controlled Electronic Tensile Testing Machine or as your need.

Detail Features About Universal Testing Machine

Main Features About Universal Testing Machine

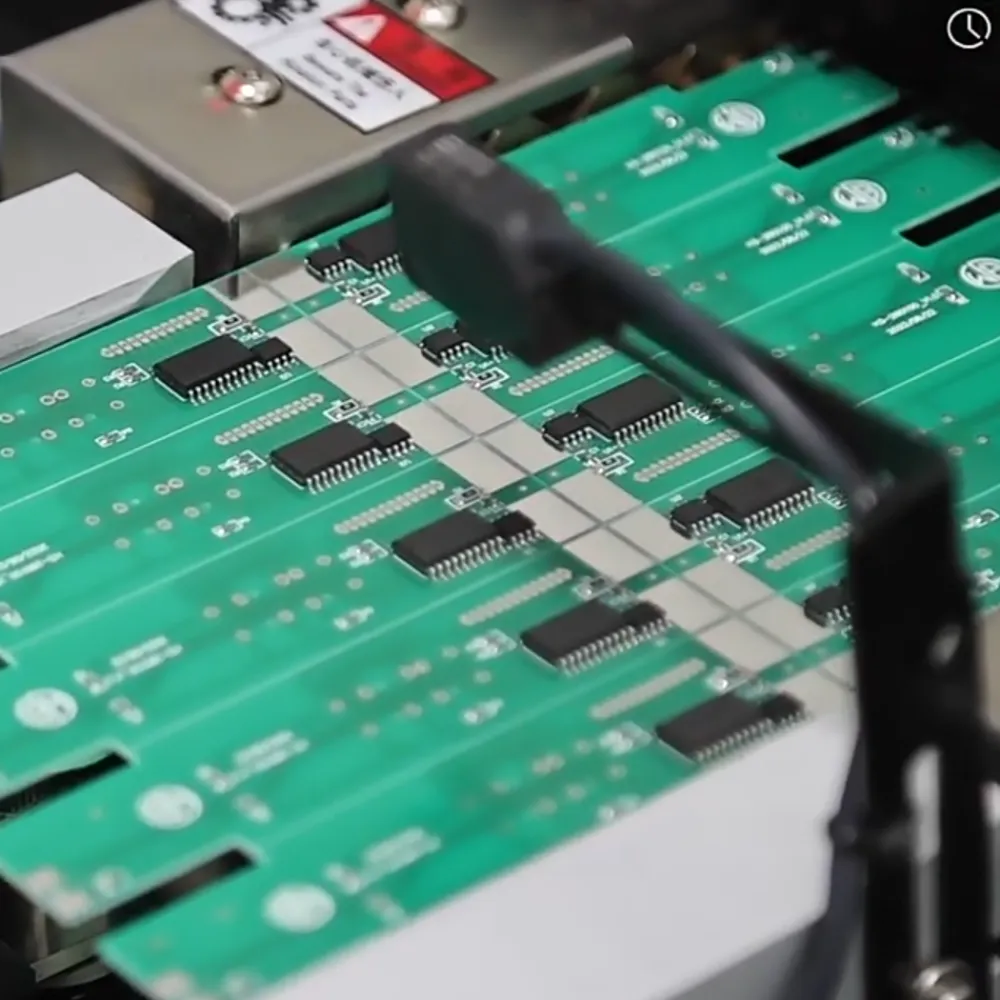

The machine incorporates a high-precision, stable-performance AC servo drive system and motor, along with Windows 7-based software for control and data processing that leverages virtual instrumentation technology to replace traditional digital displays and oscilloscopes.

It enables on-screen display of testing force, peak force, crossbeam displacement, specimen deformation, and test curves, all operable via mouse clicks, offering an intuitive, user-friendly interface. An integrated dual-channel digital control amplifier in the PC allows for physical zeroing, gain adjustment, and automatic zero and calibration for force measurement without any analog control components, resulting in simplified structure and reliable performance.

Applicable Standards of Universal Testing Machine

| Standard Code | Description |

| GB/T 16491-2008 | “Electronic Universal Testing Machines” |

| GB/T 2611-2007 | “General Technical Requirements for Testing Machines” |

| GB/T 228.1-2010 | “Metallic Materials—Tensile Testing Part 1: Method at Room Temperature” |

| Applicable International Standards | GB, JIS, ISO, ASTM, DIN |

| Packaging ad Transport Standard | GB/T 13384-1999 |

Main Frame and safety

Composed of a working table, middle beam, upper beam, guiding columns, and outer shell. The floor-standing portal structure provides upper space for tensile tests and lower space for compression and bending, with an upper-tensile, lower-compression dual-space design. It features imported backlash-free ball screws and guide rails, offering safety, rigidity, and high coaxiality.

Includes crossbeam displacement limit protection, overload protection, and break-stop protection functions to ensure safe and reliable operation.

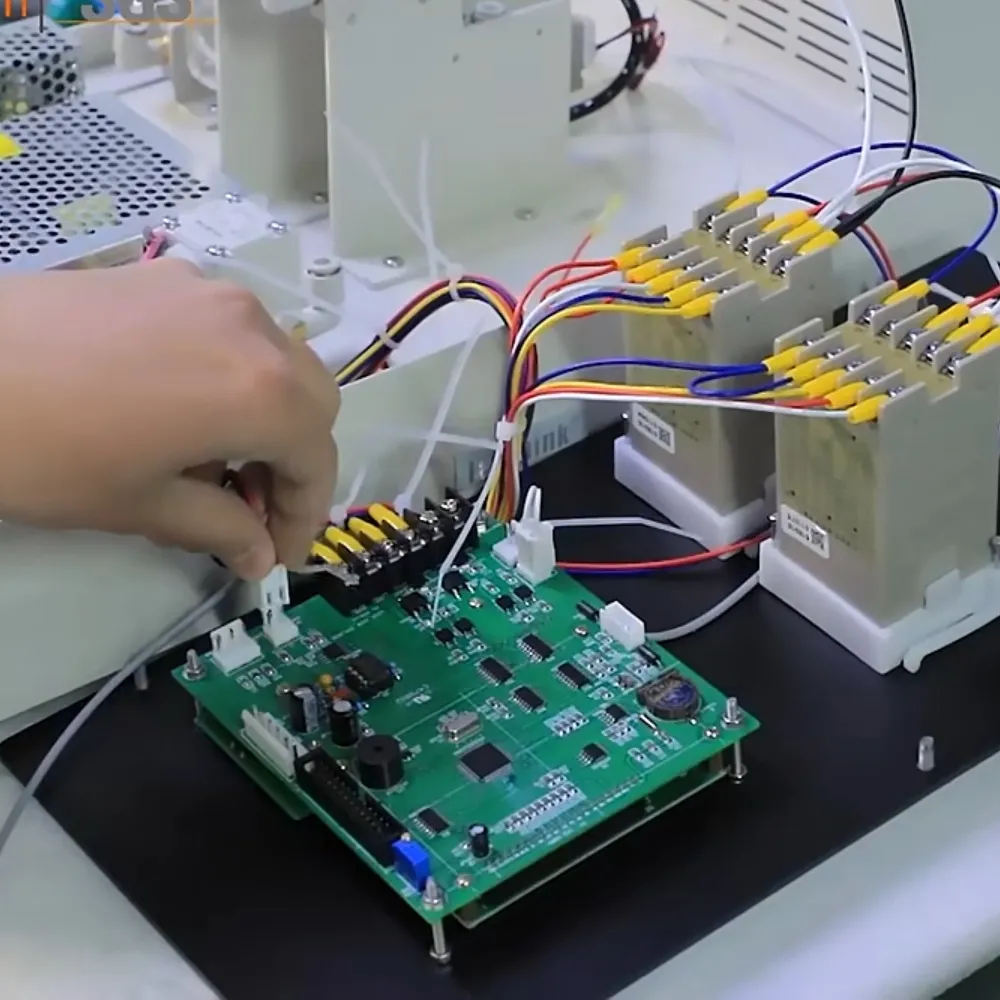

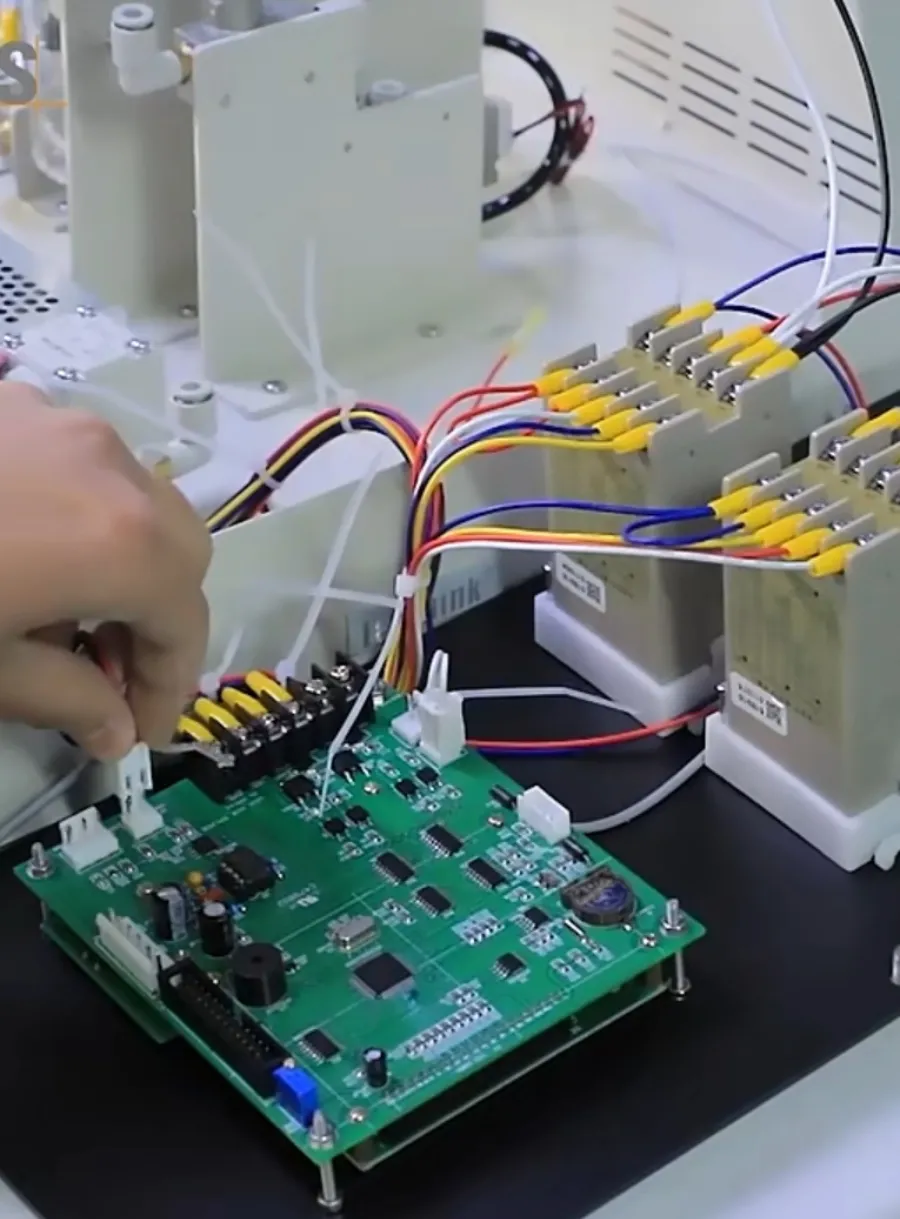

Drive System and control system

The AC servo control motor, regulated by a high-precision speed control system, drives the high-precision ball screw mechanism for smooth crossbeam movement, enabling tensile, compression, and bending tests. The arc-toothed synchronous belt system provides high efficiency, long life, low noise, and maintenance-free, backlash-free vertical movement of the crossbeam.

Operates on Windows 7/10 in Chinese, combining a full-digital PC control card with multi-channel I/O and an optical displacement system, utilizing various computer resources for a reliable, advanced system.

Precision Testing System

Equipped with a Lenovo PC for setting up tests, controlling operational states, data collection, processing, display, and printing of test results. The dedicated Windows XP-based intelligent software package allows measurements according to national and international standards, or customer specifications, with test data processing and statistical analysis. Outputs reports and characteristic curves in required formats.

Automatic Functions of Universal Testing Machine

Feature |

Description |

|---|---|

|

Automatic Zeroing |

Automatically resets to zero upon test initiation. |

|

Automatic Return |

Recognizes specimen fracture and automatically returns the crossbeam to the starting position. |

|

Automatic Range Adjustment |

Automatically switches to the appropriate load range based on the load, ensuring measurement accuracy. |

|

Auto Save |

Automatically saves test data and conditions to prevent data loss due to sudden power outages or missed saves. |

|

Variable Speed |

Crossbeam speed adjusts automatically based on preset programs or manually during the test. |

|

Automatic Calibration |

Ensures accurate measurement through automatic calibration of indications. |

|

Testing Process |

Entire test process, measurement, display, and analysis are managed by the microcomputer. |

Feature |

Description |

|---|---|

|

User Interface |

Windows XP interface with menu prompts and simple mouse operations. |

|

Dynamic Display |

Displays data and curves in real-time during the test. |

|

Results Retrieval |

Test results can be saved, retrieved, and re-analyzed as needed. |

|

Curve Analysis |

After test completion, point-by-point force and deformation data on the curve are accessible via mouse. |

|

Comparative Results |

Displays characteristic curves for multiple samples with different colors, zooming in for detailed analysis. |

|

Curve Selection |

Selects stress-strain, force-displacement, or other curves for display and printing as needed. |

|

Batch Testing |

Enables sequential testing of multiple samples with similar parameters after one-time setup. |

|

Customizable Reports |

Generates test reports formatted per user requirements for easy printing. |

Software Interface of Universal Testing Machine

Technical Dates of Universal Testing Machine

Specification |

Parameter |

|---|---|

|

Max Testing Force |

20KN (2 tons) (Optional: 5, 10KN) |

|

Accuracy Class |

0.5 |

|

Force Measurement Range |

0.2%—100% F.S |

|

Indication Error |

≤ ±1% |

|

Force Resolution |

1/300000 full-range, unchanged |

|

Displacement Rate Adjustment |

0.1–500 mm/min |

|

Tensile Stroke |

750 mm (excluding grips) |

|

Compression Stroke |

750 mm (excluding grips) |

Specification |

Parameter |

|---|---|

|

Compression Stroke |

750 mm (excluding grips) |

|

Power Supply |

220V AC, 50Hz |

|

Machine Power |

1.0 KW |

|

Working Environment |

Room temperature to 40°C, 20%–80% humidity |

|

Software Interface |

Chinese application software on Windows 7 |

|

Dimensions |

720 × 550 × 1800 mm (approx.) |

|

Weight |

260 kg (approx.) |

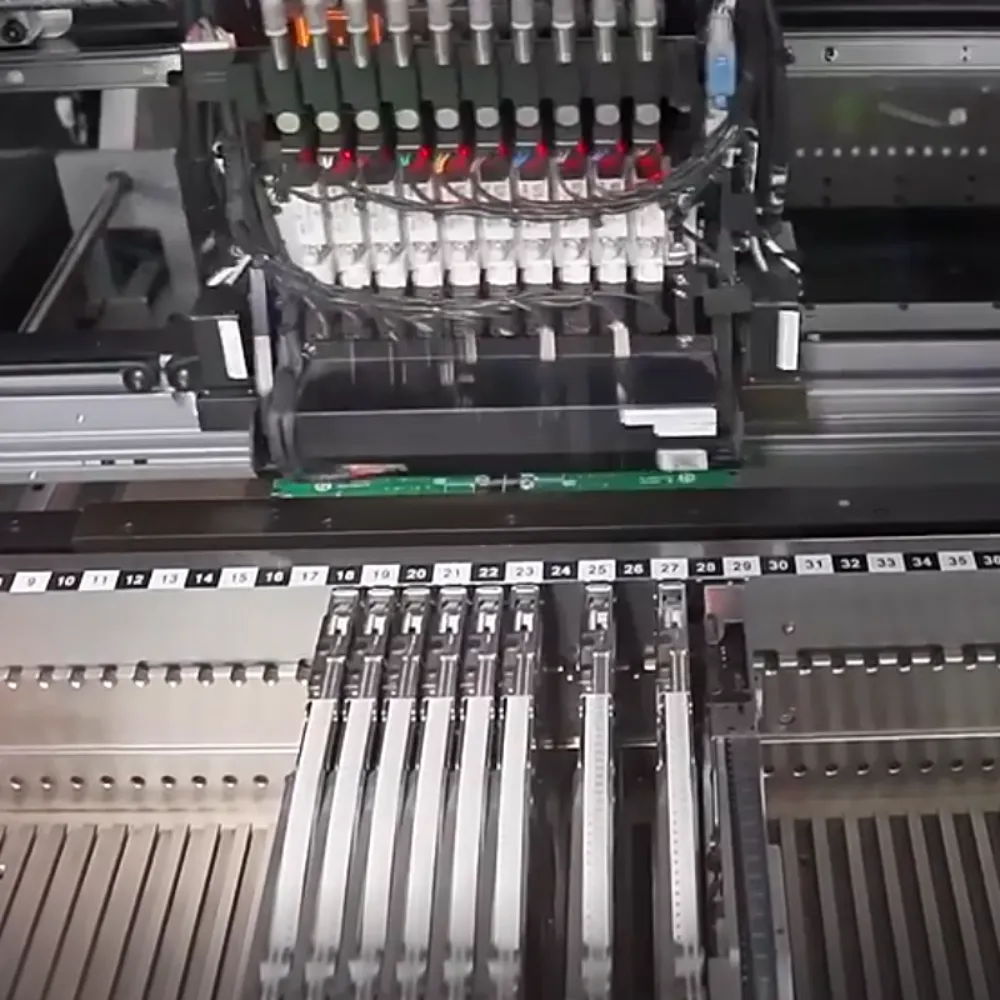

Product Configuration of Universal Testing Machine

Component |

Quantity |

|---|---|

|

Testing Machine Main Frame |

1 set |

|

Servo Motor |

1 set |

|

Drive System |

1 set |

|

High-Precision Load Sensor |

1 unit |

|

High-Precision Ball Screw |

1 pair |

|

Precision Deceleration System |

1 set |

|

Precision Testing System |

1 set |

|

Remote Control Box |

1 set |

|

Grips |

1 set |

|

Desktop Computer |

1 set |

|

Desktop Printer |

1 set |

|

Chinese Control Software |

1 set |

|

Backup USB |

1 set |

|

Technical Documents (Manuals, Certificates) |

1 set |

Invest in High Tech Lab Equipment

Enhance your business profitability with this advanced device

Frequently Asked Question

The WDW Series is versatile, capable of performing various mechanical tests such as tension, compression, bending, and shearing on diverse materials. It is suited for metals, plastics, rubber, textiles, and composite materials, making it ideal for industries like automotive, aerospace, construction, and manufacturing. The machine’s multi-functional clamps and accessories enable it to adapt to different testing scenarios, from standard tensile tests to complex cyclic tests.

The WDW Series is equipped with a computer-controlled AC servo motor, providing precise control over parameters like loading force and displacement. This automation ensures high accuracy in measurement and repeatability. The system also allows real-time data visualization and analysis, simplifying the test process and minimizing manual errors, which is essential for research and quality control environments.

This machine complies with various international testing standards, including ISO, ASTM, JIS, and BS. Compliance ensures that the results are globally recognized and compatible with industry norms, making the machine suitable for both commercial and regulatory testing needs.

The WDW Series offers several connectivity options, including USB, PCI, and RS232. This flexibility allows seamless integration with existing laboratory information systems and easy data export for further analysis, report generation, or remote monitoring of tests.

Advanced Differential Pressure Technology

Built on a highly accurate differential pressure testing principle, this gas permeability tester ensures reliable and precise measurements of gas transmission rates.

It is specifically engineered for a wide range of materials, making it versatile across industries for oxygen, carbon dioxide, nitrogen, and air permeability testing.

Independent Multi-Chamber Design

Equipped with three fully independent test chambers, this instrument allows simultaneous testing of up to three samples, which can be identical or different. This setup improves testing efficiency and flexibility, enabling labs to manage diverse testing needs with a single device.

Comprehensive Automated Control System

Featuring an intelligent one-touch operation system, this tester automates the entire process, from pressure control to test completion. Integrated software with data encryption ensures secure data handling, storage, and export, facilitating seamless data management and historical trend analysis.

Enhanced Customization and Safety Features

The tester is highly customizable, supporting specialized attachments for testing flammable, explosive, or toxic gases, along with GMP-compatible software options for industries with strict regulatory requirements. The system also offers robust self-diagnostic and data recovery functions to ensure continuous operation even under unexpected power outages.

Send us mail

Thanks for your inquiry, we will reply you within 12 Hours. Also you can add our WhatsApp for the quick reply.