Aluminum Foil Pinhole Detector

Introduction of Aluminum Foil Pinhole Detector

The Aluminum Foil Pinhole Detector complies with the requirements for pinhole detection in pharmaceutical aluminum foil as specified in YBB00152002-2015.

Standard

- YBB00152002-2015 Pharmaceutical Aluminum Foil

Configuration

- Standard Configuration: Pinhole observation stage, observation magnifier, power cable, technical documentation

Technical Dates of Aluminum Foil Pinhole Detector

Parameter |

Specifications |

|---|---|

|

Power Options |

15W, 30W, 45W selectable |

|

High-transparency Glass Panel |

— |

|

Observation Area |

400 × 250 mm |

|

Transmitted Light Illuminance |

1000 Lux |

|

Ambient Light Illuminance |

20–50 Lux |

|

Magnification Scale Value |

0.1 mm |

|

Objective Lens Magnification |

40X high-definition |

|

Minimum Measurement Value |

0.01 mm |

|

Dimensions |

800 × 600 × 300 mm (L × W × H) |

|

Weight |

20 kg |

Testing Principle of Aluminum Foil Pinhole Detector

Under specified lighting conditions and using a lightbox, the transparency of aluminum foil pinholes is utilized to observe the number of pinholes on the pharmaceutical aluminum foil inspection stage, and to measure their size.

Invest in High Tech Lab Equipment

Enhance your business profitability with this advanced device

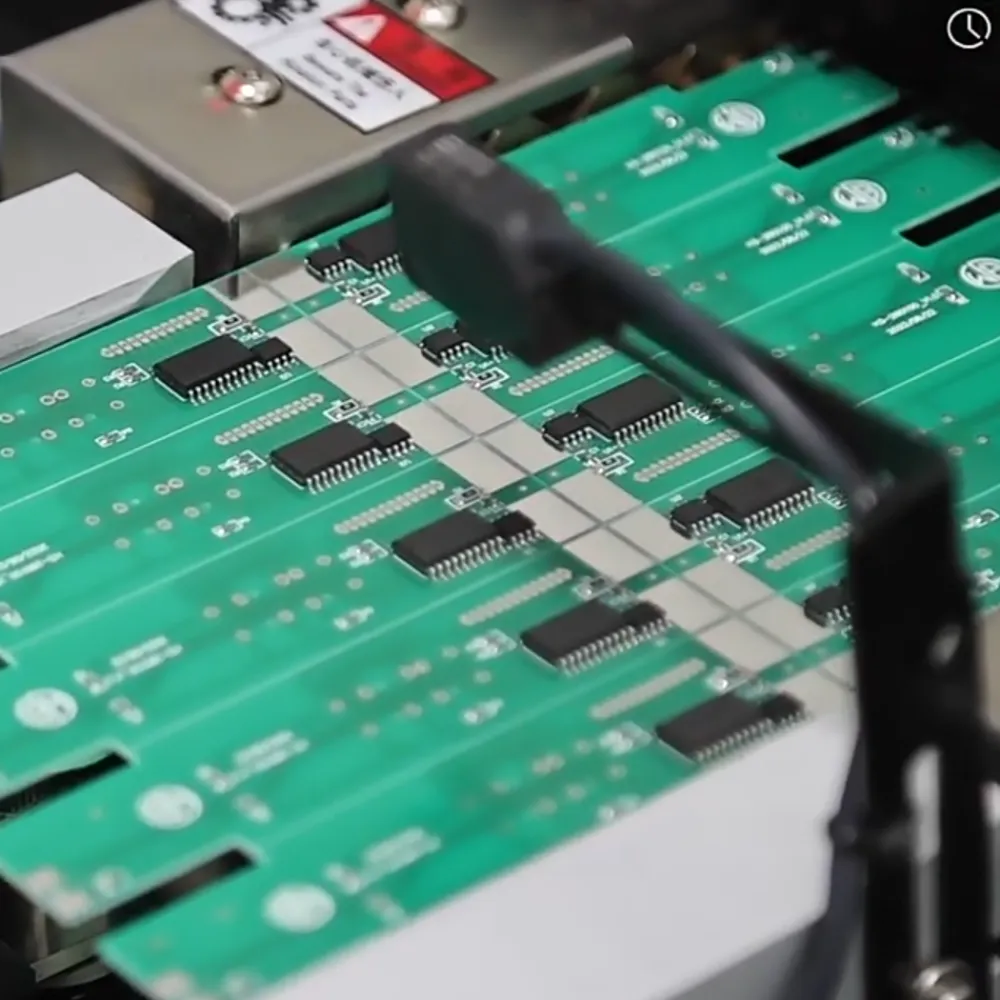

Advanced Differential Pressure Technology

Built on a highly accurate differential pressure testing principle, this gas permeability tester ensures reliable and precise measurements of gas transmission rates.

It is specifically engineered for a wide range of materials, making it versatile across industries for oxygen, carbon dioxide, nitrogen, and air permeability testing.

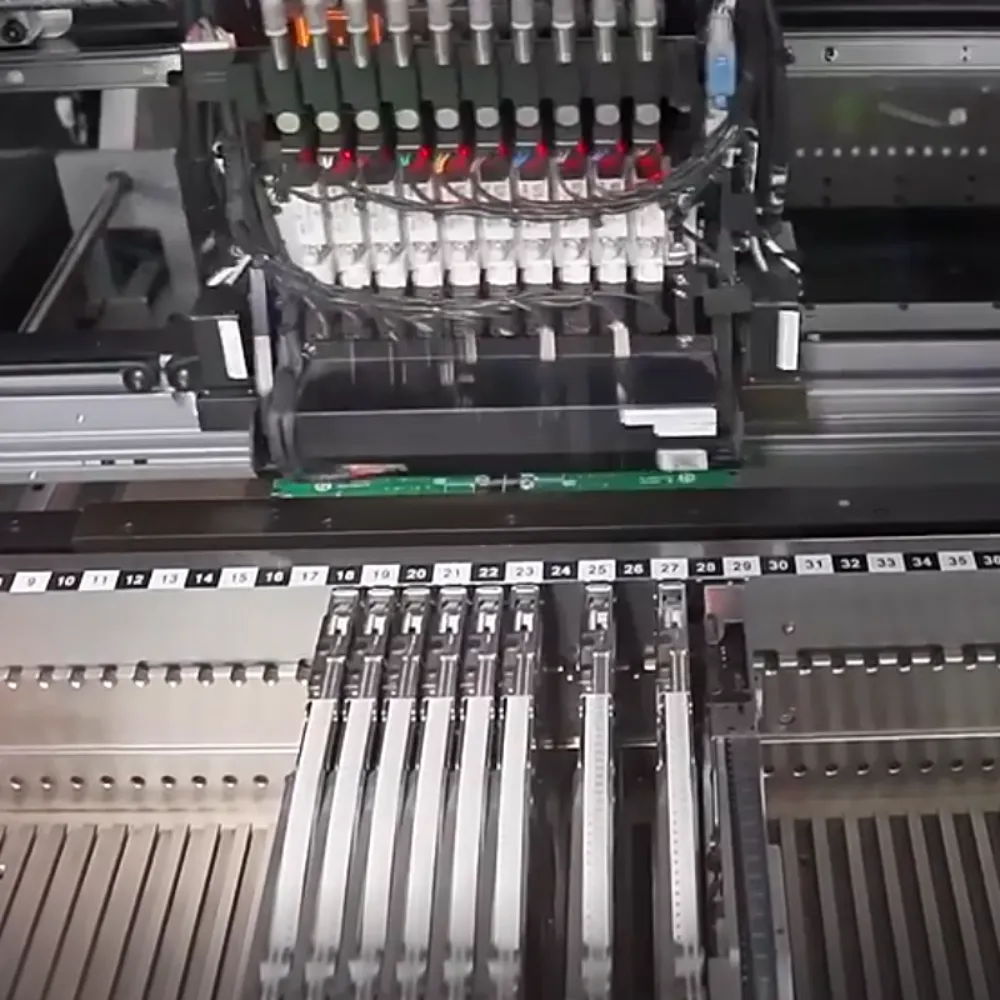

Independent Multi-Chamber Design

Equipped with three fully independent test chambers, this instrument allows simultaneous testing of up to three samples, which can be identical or different. This setup improves testing efficiency and flexibility, enabling labs to manage diverse testing needs with a single device.

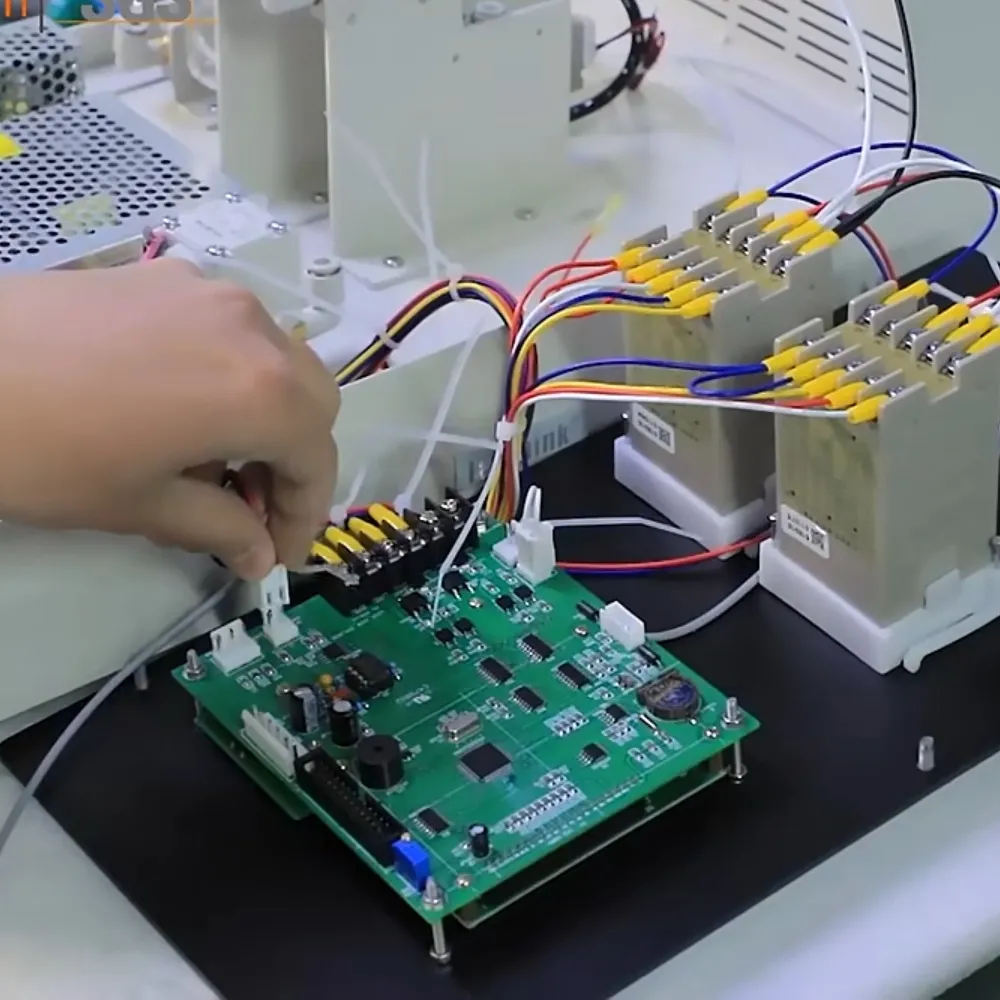

Comprehensive Automated Control System

Featuring an intelligent one-touch operation system, this tester automates the entire process, from pressure control to test completion. Integrated software with data encryption ensures secure data handling, storage, and export, facilitating seamless data management and historical trend analysis.

Enhanced Customization and Safety Features

The tester is highly customizable, supporting specialized attachments for testing flammable, explosive, or toxic gases, along with GMP-compatible software options for industries with strict regulatory requirements. The system also offers robust self-diagnostic and data recovery functions to ensure continuous operation even under unexpected power outages.

Send us mail

Thanks for your inquiry, we will reply you within 12 Hours. Also you can add our WhatsApp for the quick reply.