Intelligent Electronic Tensile Testing Machine

Introduction of Intelligent Electronic Tensile Testing Machine

Intelligent Electronic Tensile Testing Machine is specially designed for testing the tensile, peel, deformation, tear, heat seal, adhesion, puncture, opening force, low-speed unwind force, and peel force of a wide range of materials, including plastic films, composites, flexible packaging, plastic tubes, adhesives, adhesive tapes, medical patches, medical devices, release paper, protective films, composite covers, metal foils, diaphragms, backplane materials, non-wovens, rubber, and paper products.

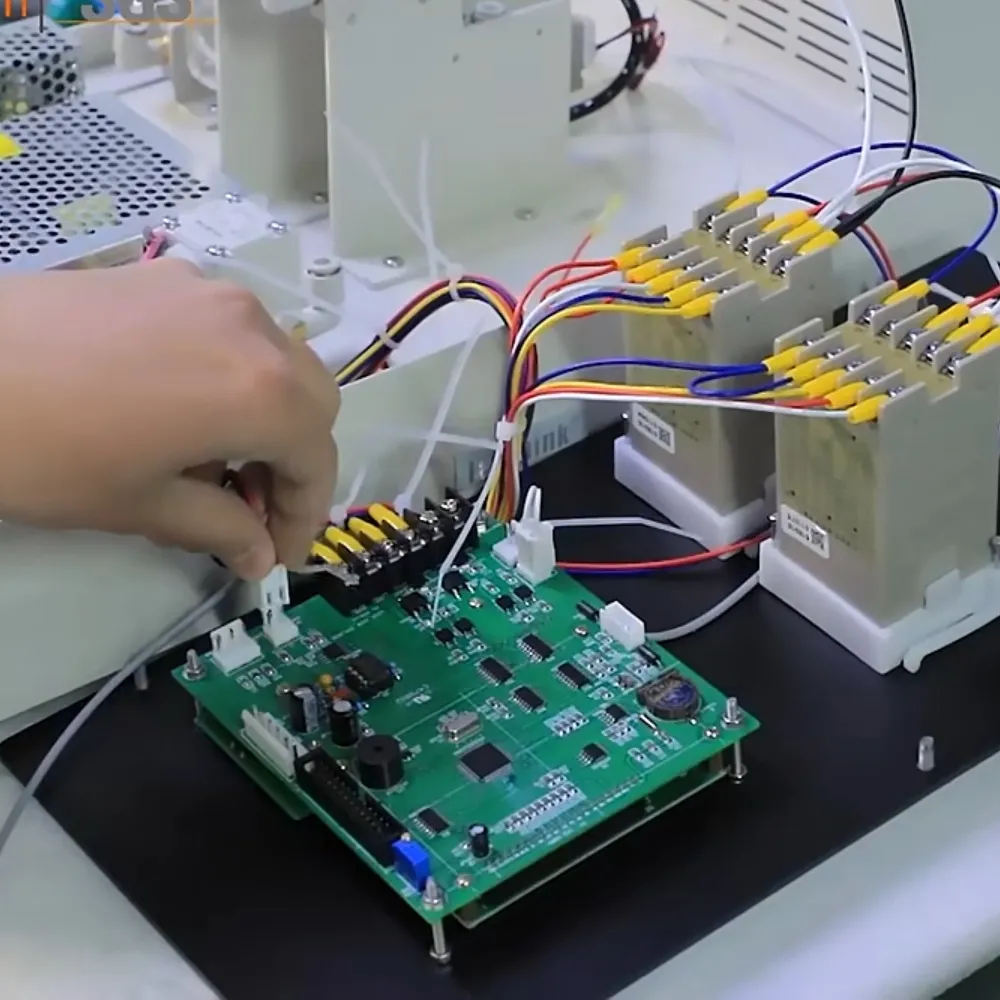

Product Configuration

- Standard Configuration: Main unit, standard grips, mini printer.

- Optional Accessories: Standard pressing roller, test board, sample cutter, non-standard grips, and non-standard load cells.

Detail Features About Intelligent Electronic Tensile Testing Machine

- 8-inch Industrial-Grade Color Resistive Touch Screen: Clear view, menu interface, sensitive touch, and easy operation.

- Integrated Testing Programs: Offers independent test modes such as tensile, peel, heat seal, tear, opening, and puncture, providing multiple test options for users.

- Bidirectional Testing Mode: Supports adjustable forward and return speeds for both tensile and compressive tests.

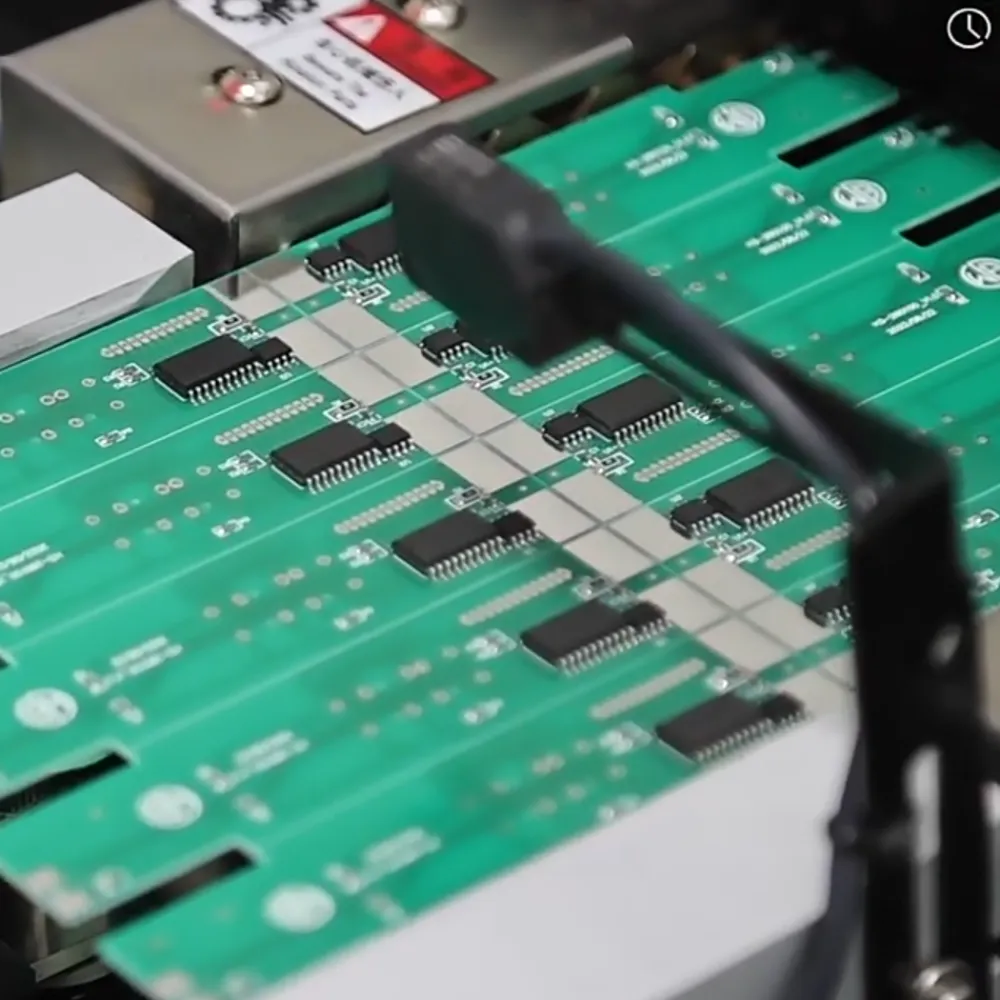

- High-Precision Force Sensor: Equipped with a high-precision load cell from a renowned brand, with testing accuracy better than 0.5 level to ensure reliable results.

- Imported High-Speed Sampling Chip: Ensures the accuracy, real-time performance, and repeatability of test results.

- Various Load Cell Options: Available in multiple specifications, making it convenient for different testing conditions.

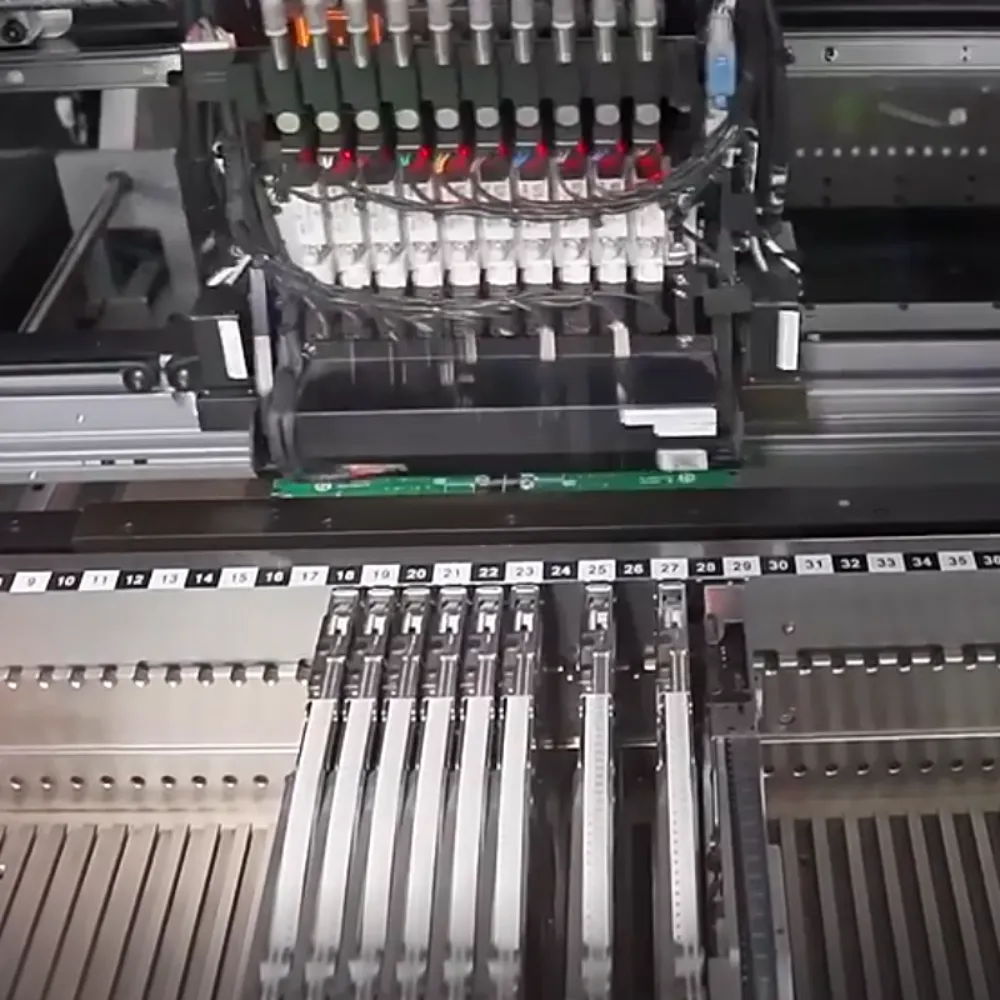

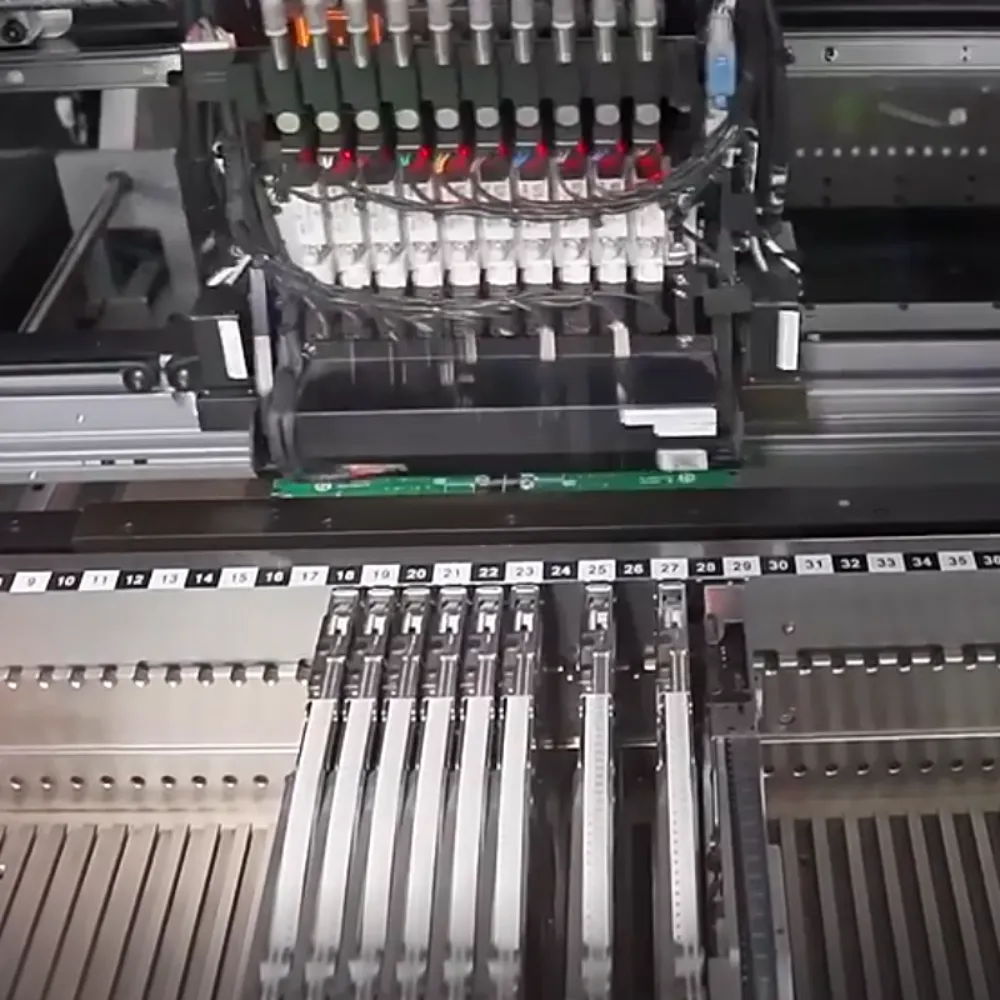

- Advanced Motor Drive System: Powered by a motor from a reputable brand, paired with precision ball screw positioning technology, achieving a positioning accuracy of 0.1mm with stepless speed adjustment for smooth operation.

- Manual and Pneumatic Clamping System: Prevents sample slippage, ensuring convenient and accurate testing.

- Extensive Application Expansion: Comes with various sample grips to accommodate testing of over 1,000 types of materials.

- Smart Safety Features: Includes limit protection, overload protection, and auto-return functions for safe operation.

- Real-Time Test Curve Display: Visualizes force variation trends throughout the testing process.

- Historical Data Access and Quick Report Printing: Enables fast data review and quick test report printing.

- Multi-Level User Permissions and Data Integrity: Supports GMP-compliant data integrity for regulated testing environments (optional).

- Built-In Mini Printer: Prints test data in real time.

- USB Interface and Specialized Control Software: Facilitates PC connectivity and data import/export (optional).

Testing Principle

The sample is clamped between two grips that move relative to each other. The force sensor on the movable grip and the displacement sensor inside the machine collect force and displacement data during the test, allowing for calculations of tensile, tear strength, deformation rate, and other performance indicators.

Reference Standards

ISO 37, GB 8808, GB/T 1040.1-2006, GB/T 1040.2-2006, GB/T 1040.3-2006, GB/T 1040.4-2006, GB/T 1040.5-2008, GB/T 4850-2002, GB/T 12914-2008, GB/T 17200, GB/T 16578.1-2008, GB/T 7122, GB/T 2790, GB/T 2791, GB/T 2792, GB/T 17590, ASTM E4, ASTM D882, ASTM D1938, ASTM D3330, ASTM F88, ASTM F904, JIS P8113, QB/T 2358, QB/T 1130, and others.

Technical Dates of Customized Intelligent Electronic Tensile Testing Machine

Parameter |

PC Model |

H Model |

|---|---|---|

|

Test Height |

300mm-600mm (optional range of 300mm-900mm) |

300mm-600mm (optional range of 300mm-900mm) |

|

Load Cell Brand |

Domestic (Dayang) |

Imported (Transcell, USA) |

|

Force Accuracy |

Better than 0.5 level |

|

|

Resolution |

0.001 N |

|

|

Drive Motor |

Stepper Motor |

Servo Motor |

|

Drive Mechanism |

Domestic Ball Screw |

Taiwan Hiwin Ball Screw |

|

Test Speed |

0 ~ 500 mm/min (Stepless) |

|

|

Speed Accuracy |

±0.5% of reading |

|

|

Sample Width |

30 mm (Standard Grip) |

50 mm (Optional Grip)

|

|

Sample Clamping |

Manual Clamp

|

Pneumatic Clamp |

|

Stroke |

1000 mm (Customizable) |

|

|

Dimensions |

450 mm (L) × 450 mm (W) × 1380 mm (H) |

|

|

Power |

AC 220 V, 50 Hz |

|

|

Net Weight |

Approx. 75 kg |

Invest in High Tech Lab Equipment

Enhance your business profitability with this advanced device

Frequently Asked Question

The XLW Series is capable of performing a wide variety of tests, including tensile, peel, deformation, tear, heat seal, adhesion, puncture, opening force, low-speed unwind force, and peel force tests. This makes it suitable for analyzing the physical properties of diverse materials such as plastic films, composites, flexible packaging, adhesive tapes, medical devices, metal foils, non-wovens, and rubber, among others.

The machine is equipped with a high-precision force sensor from a reputable brand, providing testing accuracy better than 0.5 level. Additionally, it incorporates an imported high-speed sampling chip that ensures real-time data collection and repeatability of results. The precision ball screw drive system allows for a positioning accuracy of 0.1 mm, enhancing the reliability of the testing process.

The XLW Series features an 8-inch industrial-grade color resistive touch screen with a clear, menu-based interface that makes operation straightforward. It also offers integrated testing programs with multiple modes (tensile, peel, heat seal, etc.) and real-time test curve display, enabling easy monitoring. Additionally, the machine comes with manual and pneumatic clamping options to ensure sample stability during testing.

Yes, the machine supports advanced data management features. It provides historical data access and quick report printing through its built-in mini printer. For enhanced data handling, the USB interface allows PC connectivity for importing and exporting data. The system can also be configured with specialized control software and multi-level user permissions to ensure GMP-compliant data integrity, if required.

Advanced Differential Pressure Technology

Built on a highly accurate differential pressure testing principle, this gas permeability tester ensures reliable and precise measurements of gas transmission rates.

It is specifically engineered for a wide range of materials, making it versatile across industries for oxygen, carbon dioxide, nitrogen, and air permeability testing.

Independent Multi-Chamber Design

Equipped with three fully independent test chambers, this instrument allows simultaneous testing of up to three samples, which can be identical or different. This setup improves testing efficiency and flexibility, enabling labs to manage diverse testing needs with a single device.

Comprehensive Automated Control System

Featuring an intelligent one-touch operation system, this tester automates the entire process, from pressure control to test completion. Integrated software with data encryption ensures secure data handling, storage, and export, facilitating seamless data management and historical trend analysis.

Enhanced Customization and Safety Features

The tester is highly customizable, supporting specialized attachments for testing flammable, explosive, or toxic gases, along with GMP-compatible software options for industries with strict regulatory requirements. The system also offers robust self-diagnostic and data recovery functions to ensure continuous operation even under unexpected power outages.

Send us mail

Thanks for your inquiry, we will reply you within 12 Hours. Also you can add our WhatsApp for the quick reply.