Falling Ball Impact Tester

Introduction of Heat Sealer

Product Function:

The Hard Sheet Falling Ball Impact Tester is designed to assess the damage to plastic sheets with a thickness of less than 2mm when impacted by a steel ball from a specified height. It is widely used by quality inspection agencies, pharmaceutical companies, and packaging manufacturers.

Testing Principle:

The sample is cut to a specific size and clamped in the fixture. A suitable steel ball is selected and placed in an electromagnetic holder. When released, the steel ball falls freely onto the center of the sample. The test then observes the damage to the sample, and after multiple tests, the damage rate is calculated.

This instrument complies with multiple national and international standards, including YBB00212005-2015, YBB00232005-2015, YBB00222005-2015, YBB00182004-2015, YBB00202005-2015, and YBB00242002-2015.

Testing Applications:

- Basic Application: PVC Hard Sheet – Evaluates the damage to PVC plastic sheets under 2mm thick when impacted by a steel ball from the height specified in the standard.

- Extended Application: Tamper-Evident Bottle Caps – Used for impact testing of tamper-evident bottle caps under free-fall conditions.

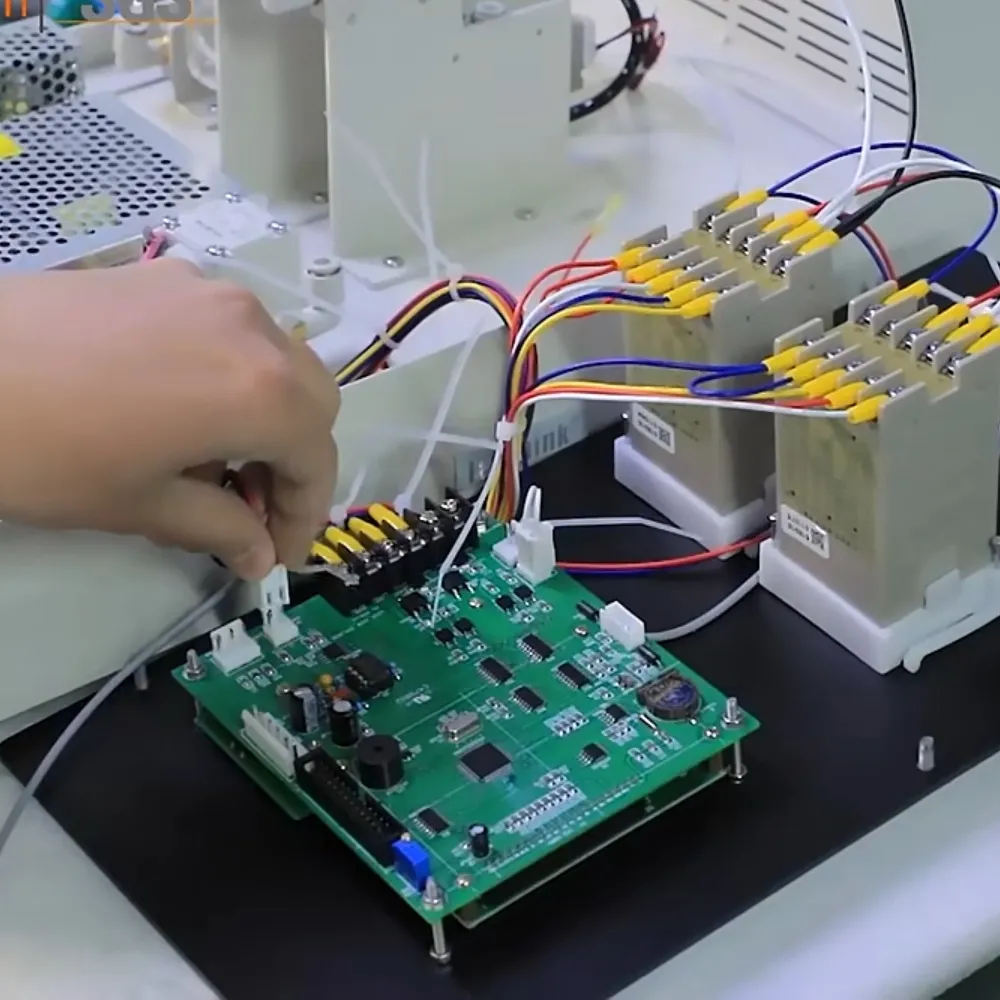

Detail Features About heat sealer

- Multiple steel ball options available to meet various standard requirements.

- Adjustable drop heights to accommodate different sample requirements.

- Pneumatic clamping and release of samples for faster and more precise testing operations.

- Electromagnetic suspension and automatic release of the steel ball to minimize human-induced errors.

- Foot pedal activation for user-friendly operation.

- Protective device for safer testing processes.

- Central positioning device for reliable test results.

Technical Dates of Customized heat sealer

Specification |

Parameter |

|---|---|

|

Test Height |

300mm-600mm (optional range of 300mm-900mm) |

|

Sample Thickness Range |

0-2mm |

|

Steel Ball Diameter |

23mm, 25mm, 28.6mm (optional 38.1mm, 50.8mm) |

|

Sample Clamping: |

Pneumatic clamping of sample |

|

Steel Ball: |

Electromagnetic absorption/release |

|

Sample Size |

>150mm×50mm |

Specification |

Parameter |

|---|---|

|

Power Supply |

AC220V, 50Hz |

|

Testing Conditions |

Temperature 10–30℃, relative humidity ≤ 85% |

|

Main Unit Dimensions |

470mm(L) × 400mm(W) × 920mm(H) |

|

Net Weight |

Approx. 30 kg |

|

Reference Standards |

YBB00212005-2015, YBB00232005-2015, YBB00222005-2015, YBB00182004-2015, YBB00202005-2015, YBB00242002-2015, etc. |

|

Standard Configuration |

Main unit + foot pedal switch + air hose + air filter + power cord + technical documentation |

Invest in High Tech Lab Equipment

Enhance your business profitability with this advanced device

Frequently Asked Question

The Hard Sheet Falling Ball Impact Tester is primarily designed to test plastic sheets with a thickness of less than 2mm. It is especially useful for assessing PVC hard sheets, composite sheets, and other similar materials. Additionally, it can be adapted to evaluate the impact resistance of tamper-evident bottle caps and similar packaging materials.

The electromagnetic release mechanism allows for a consistent and precise release of the steel ball, eliminating potential human-induced variations. This automatic release ensures that each test drop follows the exact same procedure, leading to highly reliable and repeatable test results.

Yes, the Hard Sheet Falling Ball Impact Tester offers adjustable drop heights from 300mm to 600mm (or up to 900mm with customization). Multiple steel ball sizes are also available, including 23mm, 25mm, and 28.6mm, with options for 38.1mm and 50.8mm to meet various testing standards and material requirements.

The tester is equipped with several safety features, including a protective device to prevent accidental contact during testing. The foot pedal operation mode allows hands-free activation, minimizing the operator’s exposure to potential hazards. These safety measures make the testing process both efficient and secure.

Advanced Differential Pressure Technology

Built on a highly accurate differential pressure testing principle, this gas permeability tester ensures reliable and precise measurements of gas transmission rates.

It is specifically engineered for a wide range of materials, making it versatile across industries for oxygen, carbon dioxide, nitrogen, and air permeability testing.

Independent Multi-Chamber Design

Equipped with three fully independent test chambers, this instrument allows simultaneous testing of up to three samples, which can be identical or different. This setup improves testing efficiency and flexibility, enabling labs to manage diverse testing needs with a single device.

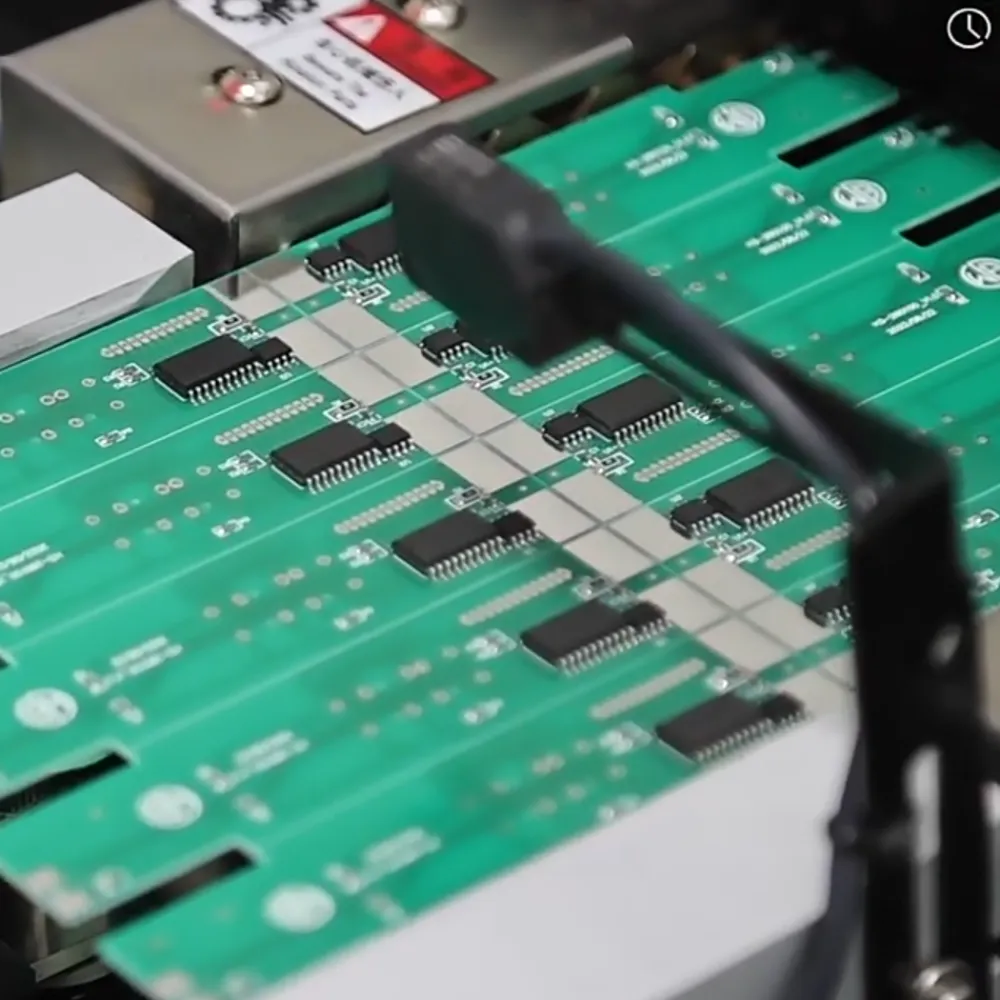

Comprehensive Automated Control System

Featuring an intelligent one-touch operation system, this tester automates the entire process, from pressure control to test completion. Integrated software with data encryption ensures secure data handling, storage, and export, facilitating seamless data management and historical trend analysis.

Enhanced Customization and Safety Features

The tester is highly customizable, supporting specialized attachments for testing flammable, explosive, or toxic gases, along with GMP-compatible software options for industries with strict regulatory requirements. The system also offers robust self-diagnostic and data recovery functions to ensure continuous operation even under unexpected power outages.

Send us mail

Thanks for your inquiry, we will reply you within 12 Hours. Also you can add our WhatsApp for the quick reply.